Why Your Factory Needs a Heavy Duty Industrial Vacuum?

Dust, debris, and spilled powders canDust, debris, and spilled powders can halt production, damage machines, and put your staff at risk. I saw this firsthand in my own facility before I upgraded our cleaning equipment[^1].

[^1]: Explore this link to discover top cleaning equipment that can enhance safety and efficiency in your facility.

, damage machines, and put your staff at risk. I saw this firsthand in my own facility before I upgraded our cleaning equipment.

A heavy duty industrial vacuum is essential for factories because it safely removes hazardous dust, debris, and liquids from production areas, reducing downtime, improving air quality, and supporting worker safety.

It’s easy to overlook cleaning devices when you focus on output or deadlines. I did that for years. But every time our old vacuums failed, operations slowed or stopped. Learning the difference the right industrial vacuum makes changed how I managed my team and protected our investments.

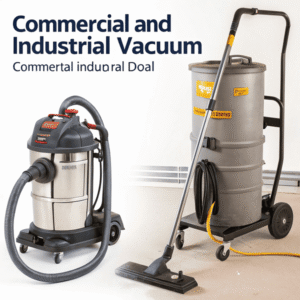

What is the difference between commercial and industrial vacuums?

When I first shopped for high-performance vacuums, the search results blurred together. It’s tough to tell whichWhen I first shopped for high-performance vacuums[^1], the search results blurred together. It’s tough to tell which model really fits your needs.

[^1]: Discover expert reviews and comparisons to find the perfect vacuum that meets your cleaning needs.

Industrial vacuums are built for large-scale, continuous-duty cleaning of factories and industrial sites, while commercial vacuums suit offices or retail spaces and handle lighter tasks with less power and capacity.

I learned this difference the hard way after burning out a “commercial” vacuum during a shift change. Industrial vacuums are made to run longer and to pick up heavier, hazardous, or bulk materials. Their motors last through years of daily use, and the filters trap even fine powders that can ruin machines or harm worker health. Commercial vacuums save money and work well for lobbies, but won’t survive harsh applications. If you’re maintaining a factory, invest in a machine that matches your floor plan and waste type.

Key Differences Table

| Feature | Commercial Vacuum | Industrial Vacuum |

|---|---|---|

| Power | Moderate | High |

| Motor Duty Cycle | Intermittent | Continuous |

| Debris Type | Dust, small debris | Heavy, hazardous, fine particles |

| Tank/Bag Size | Small-Medium | Large / Extra-large |

| Filter System | Standard (HEPA optional) | Advanced multi-stage |

| Lifespan | 1-3 years | 7+ years |

Upgrading to industrial vacuums meant our maintenance team finally kept up with the mess—and our machines stopped failing from hidden dust buildup. The extra cost soon paid for itself in saved repairs and smooth production.

Are industrial vacuums worth it?

You might look at the price tag and wonder if industrial units really save money. I thought this too until I saw what daily deep cleaning did for us.

Industrial vacuums are worth the investment for factories and production spaces because they increase cleaning efficiency, reduce costly machine breakdowns, and improve workplace health and safety.

I used to think our handheld shop vacs and “tough” commercial models could do the job. But those machines clogged fast and needed constant repairs. The switch to industrial vacuums immediately lowered our maintenance costs and nearly eliminated production stops from cleaning delays. Filters in these machines protect expensive electronics and HVAC systems, trapping fine materials that would otherwise circulate through the facility. I noticed staff morale went up too—nobody likes breathing leftover dust or fighting with broken tools in the middle of a shift.

Benefits Breakdown

| Benefit | Impact on Factory Operations |

|---|---|

| Less Downtime | Fewer breakdowns and production stops |

| Health & Safety | Reduces hazardous dust exposure |

| Cleaning Speed | Cleans larger areas quickly |

| Repair Costs | Extends equipment lifespan |

| Compliancy | Meets safety/environmental standards |

In my experience, the upfront cost of an industrial vacuum was balanced out by a drop in unplanned repairs and staff sick days. It’s an investment in both people and equipment.

What are industrial vacuums used for?

Industrial environments throw every kind of challenge at cleaning teams. I quickly realized traditional machines couldn’t keep up with our mess.

Industrial vacuums are used for removing dust, hazardous powders, metal shavings, spills, and even liquids in manufacturing plants, warehouses, and workshops. Some are designed for explosive dust or specialized industry requirements.

I always thought vacuums were just for floors, but industrial models proved me wrong. We now use ours to clear out cement dust from mixers, clean up after metal fabrication, and even collect spilled oils around the press lines. Specialized attachments get behind machines and inside ductwork. Some models handle explosion risks—critical for factories with powders like flour, sugar, or aluminum dust, which can ignite in the air. Others tackle liquids and solids together, so cleanup is fast even after major spills. The right accessories turn a simple vacuum into a multi-tool your maintenance team will use daily.

Common Industrial Vacuum Applications

| Industry | Material/Task | Special Requirements |

|---|---|---|

| Metal Fabrication | Shavings, dust, coolant | Metal filters, liquid handling |

| Food Processing | Fine powders, flour, crumbs | Explosion-proof, food-grade hoses |

| Chemical Plants | Granules, hazardous dust, spills | High filtration, anti-static parts |

| Pharmaceuticals | Powders, chemicals, dust | HEPA/ULPA filtration, containment |

| Construction | Debris, dust, spilled liquids | Wet/dry operation, heavy solids |

The switch to industrial vacuums allowed us to run more shifts, reduce slip hazards, and even pass strict regulatory inspections with less worry.

Conclusion

For factories, a heavy duty industrial vacuum is a must. It keeps machines running, people safe, and your production lines free from costly interruptions.