Finding a reliable lighting manufacturer is a huge challenge. Many promise quality but fail to deliver, leaving you with defective products and a damaged brand reputation.

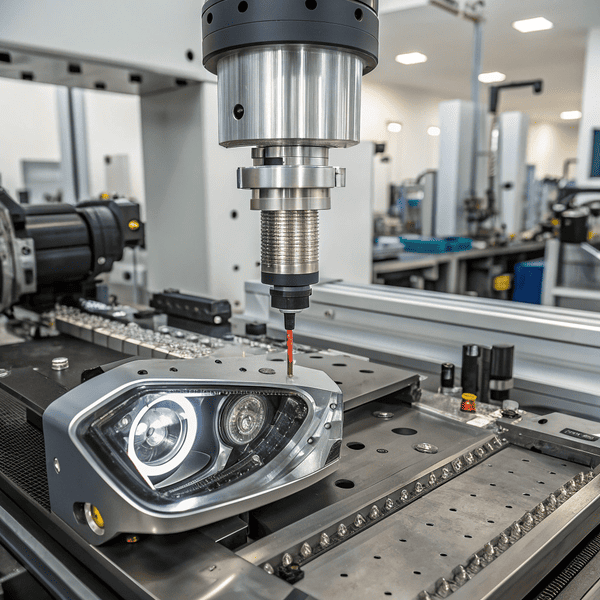

The top automotive lighting manufacturers are not just big brand names. They are factories with specialized, high-precision machinery and deep expertise in optical engineering. These suppliers are often found in specific industrial hubs like Suzhou and the Pearl River Delta, where technical skill is concentrated.

It's easy to list famous brands, but what truly separates a top-tier manufacturer from the rest? The secret isn't in their marketing budget. It's in the production details that most people never see, the small things that make a huge difference in quality. Let's look closer at what it really takes to build a great automotive light.

Why is precision injection molding so critical for car lights?

Your headlight lenses look cloudy or the light beam isn't sharp. This means poor performance, safety issues, and unhappy customers for your brand. The problem often starts with the precision of the injection molding machine.

Precision injection molding is crucial because it shapes the optical lens. Any tiny imperfection can distort the light beam, reducing visibility and safety. Standard machines just can't achieve the required accuracy for creating a perfect, clear lens that directs light exactly where it's needed.

Making automotive lights is much harder than people think. The production process involves at least three major steps, but the most difficult by far is shaping the optical lens. This requires incredible accuracy. If the mold is off by even a fraction of a millimeter, the light pattern will be completely wrong. Standard injection molding machines just can't handle this. Their precision isn't good enough for optical components.

The Difference in Machinery

This is why location matters. High-precision machines capable of this work are usually found in specific regions like the Pearl River Delta and around Suzhou. These areas have a long history of specialized manufacturing. Factories in other areas, for example in Shandong, often use machines that don't meet the strict accuracy requirements for optical lenses. It’s not just about having a machine; it’s about having the right machine and the skilled people to run it.

| Feature | High-Precision Machine | Standard Machine |

|---|---|---|

| Tolerance | Extremely low (microns) | Higher, unsuitable for optics |

| Material Flow | Perfectly controlled | Inconsistent |

| Lens Clarity | Crystal clear | Potential for haze or flaws |

| Light Pattern | Sharp and accurate | Distorted and unsafe |

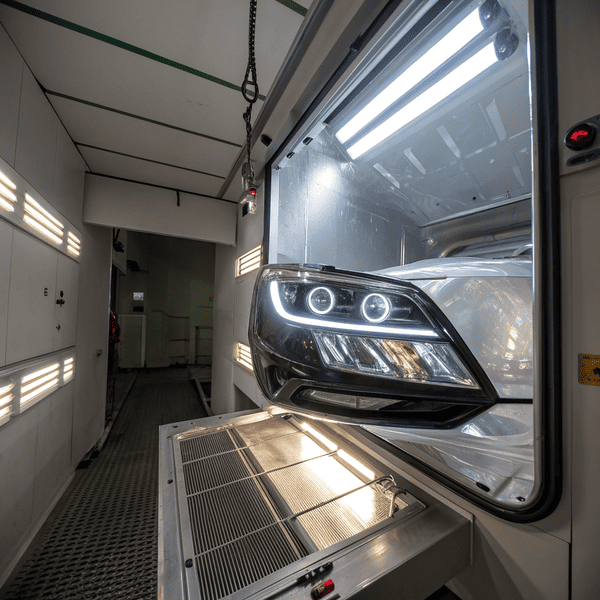

What makes reflective layer coating so difficult?

The reflective surface inside your light housing is peeling or looks inconsistent. This causes poor light output and a short product lifespan, which hurts your brand's reputation for quality. The difficulty lies in a very sensitive coating process.

Coating the reflective layer is difficult because it requires stopping the machine and opening the mold. This causes temperature fluctuations that can ruin the coating's uniformity and adhesion. Achieving a perfect, durable reflective surface demands incredible process control and specialized equipment.

The second hardest part of making a car light is applying the reflective coating. This is the shiny, mirror-like surface inside the headlight that directs the light forward. The process itself is very delicate. To apply the coating, we have to stop the machine and open the mold. The moment we do that, the temperature inside starts to drop and becomes unstable. This temperature change is the enemy of a perfect coating. If it's not managed perfectly, the coating won't stick properly or will be uneven.

My First Big Coating Challenge

I remember my first project with a German client. We were new to this specific type of light. After we applied the coating, we tested the lights and the light refraction was way off. The beam was not pointing where it should. I was worried we had failed. But the client tested it in a different real-world scenario than we expected. It turned out the "mistake" actually created a light effect they liked even more. We got lucky that time, but it was a valuable lesson. Since then, we have perfected our process to control the temperature, and we haven't made that mistake again.

How can you identify a truly capable OEM/ODM lighting partner?

Many suppliers claim to be experts, but it's very hard to know who to trust. Choosing the wrong partner means you will face costly delays, serious quality problems, and maybe even a failed project. You need to look for specific signs of real manufacturing skill.

A capable OEM/ODM partner openly discusses their machinery, quality control, and process challenges. They can explain their solutions for precision molding and coating. Ask to see their equipment and past projects. True experts are proud of their technical capabilities and are transparent about them.

When you are looking for a factory to produce your lighting products, you have to dig deeper than the sales pitch. The best partners are not afraid to talk about the hard parts. They will show you the advanced machinery they use and explain how they solve complex problems like temperature control during coating. A good manufacturer is a problem solver, not just an assembler. You should always ask detailed questions to see if they truly understand the science behind making a great light.

Key Questions to Ask a Potential Manufacturer

To protect your business, you need to ask the right questions. Here are a few essential ones I always recommend:

- What specific models of injection molding machines do you use for optical lenses? A good factory will tell you the brand and specs. They know that this machine is the heart of their quality.

- How do you manage temperature stability during the reflective coating process? Their answer will reveal if they understand and have solved this critical challenge.

- Can you show me examples of complex optical components you have manufactured before? This proves they have real-world experience, not just theoretical knowledge.

- What is your quality control process for beam pattern and light output? They should mention specific testing equipment like a goniophotometer.

A factory that can answer these questions with confidence is a partner you can trust.

What role does location play in finding a quality manufacturer?

You are searching for suppliers online, but the geography seems random. You might end up working with a factory in a region that simply lacks the specialized skills and equipment you need for a high-quality product.

Location is very important. Top-tier automotive lighting manufacturing, especially for high-precision components, is heavily concentrated in industrial hubs like the Pearl River Delta and the area around Suzhou. These regions have the specialized machinery, skilled labor, and supply chains necessary for complex production.

When sourcing automotive lighting, where a factory is located tells you a lot about its potential capabilities. This isn't a coincidence. Certain regions have become powerful industrial clusters over many years. They have attracted the best engineers, the most advanced machinery suppliers, and a whole network of supporting industries. This creates an environment where complex manufacturing thrives. For something as technical as automotive lighting, being in one of these hubs is a major advantage.

Why Industrial Hubs Matter

Factories in places like Suzhou and the Pearl River Delta are surrounded by excellence. They have access to the latest technology and a workforce that is highly skilled in precision manufacturing. This is different from factories in other areas that may focus more on simpler, high-volume production. When we need to solve a difficult optical engineering problem, our location gives us access to a community of experts and specialized suppliers. This entire ecosystem helps us innovate and maintain extremely high quality standards. For a B2B buyer, choosing a supplier from one of these key industrial hubs reduces risk and increases the chances of getting a world-class product.

Conclusion

Finding a top lighting manufacturer means looking past brand names at the real production challenges. It's about precision molding, process control, and deep technical expertise, which we have worked hard to master.