Are your brakes making a high-pitched squeal? That annoying sound isn't just frustrating; it often points to a tiny, overlooked part. A simple component called a brake shim1 could be the solution.

A brake shim1 is a thin, multi-layered plate that fits between the brake pad and the brake caliper2. Its main job is to absorb high-frequency vibrations and act as a thermal barrier3, which stops the squealing noises commonly associated with braking and ensures a quieter, smoother stop.

As a manufacturer of automotive parts, I've spent years working on everything from complex lighting systems to the smallest components in a brake assembly4. I’ve learned that sometimes, the smallest parts make the biggest difference in performance and customer satisfaction5. The brake shim1 is a perfect example of this. It's a component that many people have never heard of, but its role is absolutely critical. Let's dive into the details of the braking system to see why this little part matters so much.

What Is a Car Brake System Made Of?

It's easy to take your brakes for granted. You press the pedal, and the car stops. But have you ever wondered about the complex system that makes this happen?

Your car's brake system6 is a hydraulic network7 designed to convert your foot's pressure into stopping power. It mainly consists of the master cylinder, brake lines, and the brake assemblies at each wheel. When you press the pedal, you're pushing fluid to create immense force.

How a Brake System Works

At our factory, we produce various components that fit into this system, so I've seen firsthand how they all work together. It’s a fascinating process that relies on precision engineering. The entire system is sealed to keep the pressure consistent and the fluid clean. If there's a leak anywhere, the system loses pressure, and braking power is reduced significantly. That’s why using high-quality, reliable parts is not just about performance; it's about safety8. Here’s a simple breakdown of the key parts and their functions.

| Component | Function |

|---|---|

| Brake Pedal | The lever you press with your foot to start the braking process. |

| Master Cylinder | Converts the force from the pedal into hydraulic pressure. |

| Brake Fluid | A special hydraulic fluid that transmits pressure through the system. |

| Brake Lines | A network of tubes and hoses that carry the fluid to each wheel. |

| Brake Assembly | The parts at the wheel that create friction to stop the car (disc or drum). |

Which Brake Parts Belong to the Disc Brake System?

Most modern cars use disc brakes, at least for the front wheels. They're known for great performance. But what are the key parts that make up this specific system?

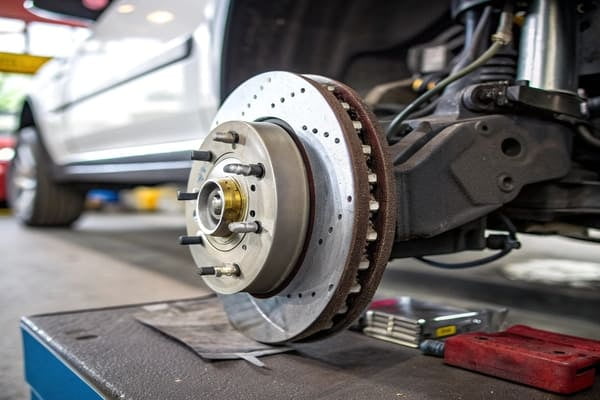

A disc brake system6 includes a caliper, brake pads9, and a rotor. These parts work together to grab the spinning wheel and slow it down. The shim is a small but important part of this assembly, ensuring everything operates quietly and smoothly.

A Closer Look at Disc Brake Components

Understanding these parts is important, especially for our clients who are distributors and brand owners. When they source parts from us, they need to know that every single component, from the large caliper to the small shim, meets strict quality standards. A failure in any one of these parts can affect the entire system's performance and the end-user's safety8. Each part has a very specific job.

| Component | Function |

|---|---|

| Brake Rotor (Disc) | A metal disc that is attached to the wheel and spins with it. |

| Brake Caliper | Houses the brake pads9 and pistons. It sits over the rotor like a clamp. |

| Brake Pads | Two pads with friction material that press against the rotor to create friction. |

| Caliper Piston | A small piston inside the caliper that is pushed by brake fluid10 to squeeze the pads. |

| Brake Shim | A thin layer fitted to the back of the brake pad to dampen noise and vibration. |

What Is a Brake Shim and Where Is It Installed?

You've heard that a brake shim1 stops noise, but what is it really? It seems too simple, but this little part has a very specific design and an important job.

A brake shim1 is a thin plate made of metal or composite materials. It is installed on the back of the brake pad, fitting between the pad's steel backing plate and the caliper piston11. Its sole purpose is to act as a buffer to absorb vibration.

The Engineering Behind a Simple Part

From a manufacturing perspective, brake shim1s are surprisingly complex. They aren't just simple pieces of metal. High-quality shims are often made of multiple layers, including steel, specialized rubber, and an adhesive. The goal is to create a material that can effectively dampen, or absorb, the tiny vibrations that occur during braking. This requires incredible precision. The shim must be cut perfectly to fit the brake pad, and the layers must be bonded together tightly to work correctly. The placement is also critical. If the shim is not perfectly seated against the brake pad backing plate, it can't do its job, and the noise will persist. It’s a great example of how a small detail in manufacturing can have a huge impact on the final product's quality and performance.

How Does a Brake Shim Reduce Noise and Vibration?

It might seem strange that a thin metal plate can stop a loud squeal. How does it actually work? The science behind it is all about managing tiny, high-speed movements.

A brake shim1 works by isolating and absorbing the high-frequency vibrations of the brake pad. When the pad presses against the spinning rotor, it vibrates. The shim creates a cushion that stops these vibrations from transferring to the caliper and the rest of the car, preventing noise.

A Lesson in Manufacturing Precision

I learned this lesson the hard way early in my career. We were working with a new Australian client to produce a line of brake pads9. At the time, I underestimated the difficulty of manufacturing shims. The process requires several steps, but the hardest part is tuning the damping performance and laminating the different layers. The machines needed for this level of precision are not common; you typically find them in specialized factories. Our first batch of shims wasn't perfect. The lamination wasn't tight enough, and the sound insulation was not as good as it should have been. When the client installed the pads, the brakes were not completely silent. I was worried, but it turned out to be a happy accident. The client was fitting them on basic commuter cars, and their customers actually liked the slight feedback from the brakes. We got lucky, but it was a valuable lesson. It taught me that in auto parts, precision is everything.

Why Do Brake Pads Squeal Without Shims?

You just replaced your brake pads9, but now they're squealing loudly. The technician may have forgotten a crucial step: installing the brake shim1s. This is a common cause of brake noise12.

Brake pads squeal without shims because there is direct metal-to-metal contact between the pad's backing plate and the caliper piston11. This allows the high-frequency vibrations from braking to transfer and amplify through the caliper, turning the whole assembly into a speaker that produces a loud squeal.

The Physics of Brake Squeal

Think of it like this: when you strike a tuning fork, it vibrates and makes a sound. If you press that tuning fork against a wooden table, the sound gets much louder because the table amplifies the vibrations. In a brake system6, the brake pad is the tuning fork. The vibration it creates is very small and at a very high frequency. Without a shim, this vibration travels directly to the caliper, which acts like the wooden table. The caliper and other connected suspension parts amplify the vibration, making it audible as a piercing squeal. The shim acts as an insulator, stopping the vibration from ever reaching the "amplifier." This is why even high-quality brake pads9 will squeal if they are installed without their matching shims. It’s not a sign of a bad pad, but simply a missing piece of the puzzle.

What Happens If Brake Shims Are Missing or Damaged?

So, you're missing brake shim1s. Besides the annoying noise, is this a serious problem? Will it affect your car's ability to stop safely?

The most common and immediate result of missing shims is loud and persistent brake noise12. While this doesn't typically reduce your immediate stopping power, the constant vibration can cause other problems over time, like uneven wear13 on your brake pads9 and rotors.

The Long-Term Consequences

For our B2B clients, like distributors and e-commerce sellers, this is a major issue. A noisy product leads to customer complaints, returns, and a damaged brand reputation. While safety8 isn't immediately compromised, the long-term effects are real. The constant vibration can cause the brake pad to move slightly in the caliper, leading to "hot spots" and uneven wear13. This means the brake pads9 won't last as long and may need to be replaced sooner. It can also cause the surface of the brake rotor14 to wear down unevenly. For us as a manufacturer, ensuring every set of brake pads9 we produce includes high-quality, properly fitted shims is a critical quality control step. It protects our clients' brands and ensures the end-user has a good experience.

| Effect | With Brake Shims | Without Brake Shims |

|---|---|---|

| Noise | Quiet, smooth operation. | Loud squealing or grinding noises. |

| Pad Wear | Even wear across the pad surface. | Potential for uneven wear13 and shorter pad life. |

| Comfort | Smooth and comfortable braking feel. | Vibrations can sometimes be felt in the pedal. |

| Brand Reputation | Positive customer experience. | Negative reviews, returns, and warranty claims. |

Conclusion

Brake shims are small but essential for modern braking systems. They prevent noise, ensure smooth operation, and protect other components from premature wear, proving that every part matters for quality.

Understanding brake shims can help you appreciate their role in reducing noise and improving brake performance. ↩

Discover how brake calipers contribute to effective braking and vehicle safety. ↩

Discover the role of thermal barriers in enhancing brake performance and safety. ↩

Learn about the parts of a brake assembly to ensure proper maintenance and safety. ↩

Learn how quality brake components contribute to a positive customer experience. ↩

Explore the intricacies of brake systems to understand how they ensure your safety on the road. ↩

Gain insights into hydraulic systems to better understand your vehicle's braking capabilities. ↩

Explore the safety aspects of brake maintenance to ensure your vehicle is roadworthy. ↩

Learn about various brake pad types to choose the best one for your vehicle's needs. ↩

Choosing the right brake fluid is essential for optimal brake system performance. ↩

Understanding the caliper piston helps you grasp how brakes generate stopping power. ↩

Understanding brake noise can help you troubleshoot and maintain your vehicle effectively. ↩

Learn about the factors leading to uneven wear to prevent costly repairs. ↩

Understanding brake rotors is crucial for maintaining your vehicle's braking efficiency. ↩