Facing 62TE transmission issues1? Ignoring them risks a complete failure. Smart upgrades can secure its long-term reliability and give you peace of mind on the road.

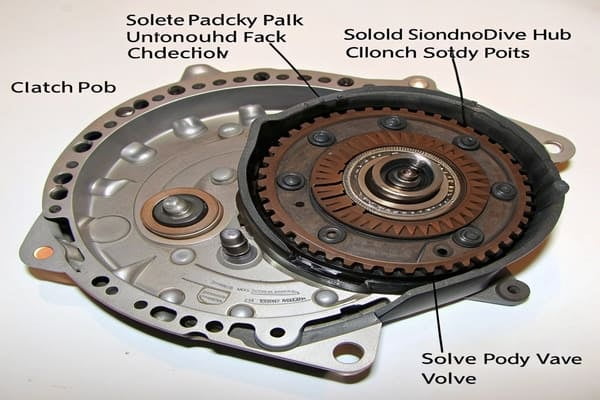

The most effective 62TE transmission upgrades target the valve body2, solenoid pack3, and clutch assembly4. Key parts include an improved solenoid switch valve plug5, a stronger underdrive clutch hub6, and enhanced cooling system components7. These address the transmission's core hydraulic and mechanical weak points for maximum reliability.

These upgrades might seem simple on paper, but the reality is much more complex. The 62TE is a notoriously finicky unit, and I've learned that a successful, long-lasting fix starts with a deep understanding of its specific weaknesses. Without knowing what breaks and why, you're just throwing parts at a problem. Let's dig into exactly where these issues come from and how the right engineering can solve them for good.

What Are the Common Weak Points in the 62TE Transmission That Require Upgrades?

Unsure where your 62TE problems originate? Guessing at fixes is expensive and ineffective. Identifying the core weak points is the first step to a permanent, reliable solution.

The primary weak points are the solenoid pack3, which controls hydraulic pressure8, the underdrive clutch hub6, which is prone to cracking, and the valve body2, which suffers from bore wear9. These issues lead to shifting problems10, torque converter clutch11 failure, and eventual transmission breakdown.

Based on my experience manufacturing and developing solutions for these units, the problems almost always trace back to a few key areas. The engineering of the 62TE has inherent flaws that become apparent over time, especially under heavy use. Breaking these down helps clarify why specific upgrades are so necessary.

The Vulnerable Solenoid Pack and Valve Body

The valve body2 is the hydraulic brain of the transmission, and the solenoid pack3 is its nervous system. Unfortunately, the aluminum bores in the valve body2 where critical valves operate tend to wear out. This wear creates gaps, allowing high-pressure fluid to leak. This loss of pressure is the root cause of countless problems, from slipping clutches to delayed shifts. Calibrating the valve body2's pressure curve after any modification is one of the most difficult steps. It requires incredibly precise machinery that I've found is common in manufacturing hubs near Fujian or Shanghai, but often lacking in other regions.

The Fragile Underdrive Clutch Hub

Another major failure point is the underdrive clutch hub6. The factory component is simply not strong enough to handle the torque, especially in heavier vehicles like minivans and SUVs. Over time, it develops stress fractures and can fail completely, leaving you with no forward gears. It's a catastrophic failure12 that often takes other components with it.

Inefficient Heat Dissipation

The 62TE transmission tends to run hot, and heat is the number one enemy of any automatic transmission. High temperatures break down the transmission fluid13, accelerate wear on soft seals, and cause clutch materials to glaze over. The stock cooling system often struggles to keep temperatures in a safe range, which shortens the life of the entire unit.

| Weak Point | Common Symptom(s) | Consequence of Failure |

|---|---|---|

| Valve Body Bore Wear | Harsh or delayed shifts, TCC shudder | Loss of hydraulic control14, clutch burnout |

| Underdrive Clutch Hub | No forward movement, grinding noises | Catastrophic internal damage |

| Inadequate Cooling | "Burnt" smelling fluid, overheating codes | Accelerated wear on all internal parts |

Which 62TE Transmission Upgrades Actually Prevent Premature Failure?

Want to upgrade your 62TE effectively? Many aftermarket parts are just temporary fixes. Focusing on engineered solutions15 that correct the original design flaws is the only way to prevent premature failure.

Upgrades that prevent failure include a redesigned solenoid switch valve plug5 and end plugs for the valve body2, a stronger, billet underdrive clutch hub6, and an upgraded torque converter lock-up valve. These parts directly address the most common points of mechanical and hydraulic failure.

After seeing countless failed transmissions, I've learned that you must address the root cause, not just the symptom. This means installing components that are fundamentally better designed than the original parts.

Reinforcing the Valve Body

To fix the leaky valve body2, you need to install oversized plugs and valves that restore hydraulic integrity. For example, a redesigned solenoid switch valve (SSV) plug made from durable, wear-resistant materials can seal the worn bore and stop the pressure loss that causes so many shifting issues. These parts are not just replacements; they are re-engineered solutions15 that permanently fix the flaw in the original design.

Upgrading the Underdrive Clutch Hub

The only real solution for the weak underdrive clutch hub6 is to replace it with a component made from a stronger material. A hub machined from billet steel is significantly more durable than the cast factory part. It can withstand much higher stress and torque loads without cracking, effectively eliminating this common and catastrophic failure12 point.

Improving the Cooling and Clutch System

Matching a reinforced clutch with the cooling system is another major challenge. When we perform this upgrade, the equipment has to be stopped, and the entire transmission assembly must be opened up. This process can be tricky and affect operational stability if not done with extreme care. An auxiliary transmission cooler16 is also a fantastic upgrade. By keeping the fluid temperature down, it extends the life of the fluid itself, the seals, and the clutches. It's a simple but incredibly effective way to build long-term reliability into the system.

| Upgrade Component | Problem Solved | Long-Term Benefit |

|---|---|---|

| Oversized SSV Plug | Valve body bore wear9 and pressure loss | Stable hydraulic pressure8, smooth shifting |

| Billet Underdrive Clutch Hub | Factory hub cracking under load | Prevents catastrophic mechanical failure17 |

| Upgraded Cooler/Clutches | Overheating and fluid breakdown | Extends life of all transmission components |

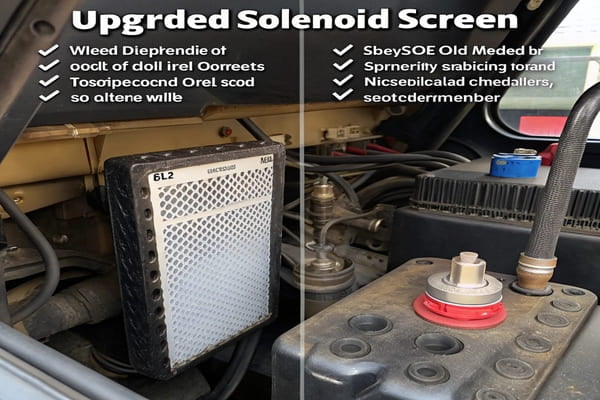

How Does a Solenoid Screen Upgrade Improve 62TE Hydraulic Stability?

Experiencing erratic shifts and pressure drops? Debris circulating in your transmission fluid13 is likely clogging vital solenoids. An upgraded screen filters better, protecting components and stabilizing hydraulic pressure8.

An upgraded solenoid screen features a finer mesh that traps more contaminants before they can enter the solenoid pack3. This prevents sticking valves and ensures consistent hydraulic pressure8, leading to smoother shifts, stable torque converter lock-up, and a longer solenoid pack3 life.

It's amazing how such a small and inexpensive part can make a huge difference in the 62TE's performance and longevity. The entire transmission relies on clean fluid to function correctly, and the solenoid screen is the last line of defense for its most sensitive components.

The Role of Clean Transmission Fluid

Transmission fluid is not just a lubricant; it's a hydraulic fluid that actuates clutches and bands to make gear changes happen. The solenoids in the 62TE are incredibly precise electro-mechanical valves that open and close hundreds of times per minute to direct this flow. They have very tight tolerances, and even a tiny piece of debris can cause a major problem. This debris comes from normal clutch wear and metal-on-metal contact inside the transmission.

How Debris Causes Solenoid Failure

When metallic and friction material particles bypass the main filter, they can get lodged in a solenoid valve, causing it to stick open or closed. This leads to all sorts of hydraulic chaos, like harsh shifts, delayed engagement, or failure to engage a gear at all. I remember an early project with a client from Pakistan. After our upgrades, he reported very harsh shifting. At first, I was worried we had made a mistake in our pressure calibration18. Luckily, he used the vehicle for heavy-duty towing and actually preferred the aggressive feel! But it taught me a valuable lesson about how sensitive these systems are to pressure and flow, which are directly impacted by fluid cleanliness.

The Upgraded Screen Solution

A standard OEM solenoid screen does a decent job, but an upgraded screen with a finer mesh is far more effective. It traps a higher percentage of the fine, damaging particles before they can ever reach the solenoids. This simple change keeps the solenoids clean and moving freely, which stabilizes hydraulic pressure8 across the entire system. The result is more consistent shift quality, reliable torque converter operation, and a much longer service life for the entire solenoid pack3.

Why Is the Solenoid Pack Area a Critical Focus for 62TE Upgrades?

The 62TE solenoid pack3 is often discussed, but why is it so vital? This one part is the brain of your transmission. Upgrading it and the area around it offers the best results for reliability.

The solenoid pack3 area is critical because it houses the solenoids that direct fluid flow for every gear change and the torque converter clutch11. Wear in the surrounding valve body2 bores causes pressure leaks, leading to almost all common 62TE shifting complaints and failures.

If you want to fix a 62TE for good, you have to start here. I've spent years developing parts for this specific area because if you don't get the hydraulics right, no amount of other upgrades will matter. The entire operation of the transmission hinges on the integrity of this system.

The Heart of Hydraulic Control

Think of the solenoid pack3 as a set of electronic faucets. The transmission control module (TCM) sends electrical signals to these solenoids, telling them when to open and close. This action directs pressurized fluid to the correct clutch pack to engage the next gear. If there's a problem here, the transmission can't execute commands correctly.

The Solenoid Switch Valve (SSV) Bore

The most critical point of failure is the bore in the valve body2 that contains the Solenoid Switch Valve (SSV). This valve is responsible for directing fluid to and from the solenoid pack3. The constant movement of the valve wears away the soft aluminum of the bore. This wear creates a gap, allowing critical line pressure to leak away. This is where the real work happens. Fixing this requires high-precision machinery to ream the bore and install an oversized, durable sleeve and valve. This is not a job for standard equipment. The precision required is immense, and the machines capable of doing it correctly are typically found in specialized factories, like the ones we partner with in coastal China.

The Domino Effect of Pressure Loss

Once pressure is lost at the SSV bore, it creates a domino effect. The torque converter clutch11 won't get enough pressure to lock up properly, leading to shudder and overheating. The clutch packs won't engage firmly, leading to slipping and accelerated wear. Shift solenoids will act erratically because their source pressure is unstable.

| SSV Bore Wear Symptom | Direct Hydraulic Cause |

|---|---|

| Torque Converter Shudder | Insufficient TCC apply pressure |

| Harsh 2-3 or 4-5 Upshift | Pressure loss in the apply circuit |

| Delayed Reverse Engagement | Leakage in the reverse clutch feed |

| P0741 Code (TCC Stuck Off) | Major pressure leak at the TCC control valve |

This is why focusing on the solenoid pack3 and the surrounding valve body2 bores with precision-engineered parts is the only way to build a truly reliable 62TE transmission.

Conclusion

Upgrading the 62TE transmission requires a targeted approach. Focusing on the valve body2, underdrive clutch, and solenoid pack3 with high-quality parts addresses its core weaknesses for long-term reliability.

Understanding common issues can help you prevent costly repairs and ensure your vehicle runs smoothly. ↩

The valve body is crucial for hydraulic control; learn how it impacts your transmission's reliability. ↩

Discover how the solenoid pack controls fluid flow and affects shifting performance. ↩

Upgrading the clutch assembly can enhance your transmission's durability and efficiency. ↩

This component is vital for hydraulic integrity; learn how it can prevent transmission issues. ↩

Understanding its weaknesses can help you choose better replacement options. ↩

Effective cooling is essential for transmission longevity; explore how to improve it. ↩

Hydraulic pressure is key to smooth shifting; learn how to maintain it. ↩

Understanding bore wear can help you prevent hydraulic failures in your transmission. ↩

Recognizing shifting problems early can lead to timely and effective solutions. ↩

Identifying issues with the torque converter clutch can save you from major repairs. ↩

Learn about the signs of impending failure to avoid costly breakdowns. ↩

Clean fluid is essential for hydraulic function; discover how to maintain it. ↩

Understanding hydraulic control is key to diagnosing and fixing transmission issues. ↩

Explore how engineered solutions can address design flaws and enhance reliability. ↩

An auxiliary cooler can significantly enhance your transmission's reliability and lifespan. ↩

Identifying mechanical failure early can help you avoid extensive repairs. ↩

Proper pressure calibration is crucial for optimal transmission performance; learn how to achieve it. ↩