Your car's brake system1 seems complex, and a single faulty part can be a huge problem. Understanding how it all works is the first step to sourcing quality components.

A car's brake system1 uses hydraulic pressure2 to clamp friction materials3 against rotating discs or drums, converting motion into heat to stop the vehicle. The main parts are the master cylinder4, brake lines5, calipers6, brake pads7, and brake rotors8, all working together when you press the pedal.

This system is one of the most critical safety features in any vehicle. It has to work perfectly every single time. As a manufacturer, I've spent years focused on the details of each component, from the raw materials to the final assembly. Getting it right is not easy, but it's essential. Let's break down how these parts work together to bring a car to a safe stop.

What Is a Car Brake System Made Of?

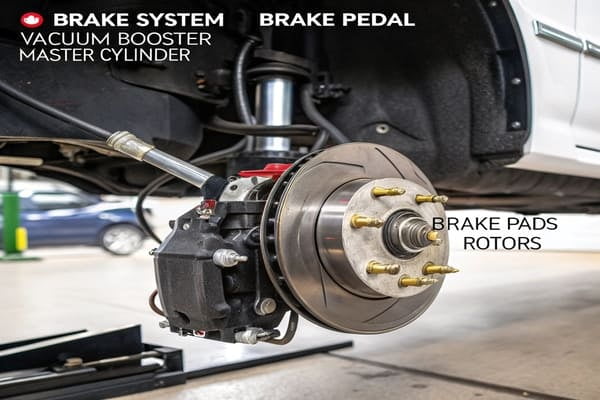

You hear the term "brake system1," but what does that actually include? Not knowing makes it hard to source the right parts or understand potential issues. Let's list the core components.

A complete car brake system1 is a hydraulic circuit. It starts with your foot on the brake pedal and ends with the car stopping. The main components are the brake pedal, booster, master cylinder4, brake lines5, calipers6, pads, and rotors.

When you press the brake pedal, a whole chain of events begins. Your foot pressure is the start, but it gets a lot of help along the way. The brake booster9 uses engine vacuum or a hydraulic pump to multiply the force from your foot. This makes braking much easier. That amplified force pushes a piston inside the master cylinder4, which is basically the heart of the system. The master cylinder4 pressurizes the brake fluid10. This fluid then travels through a network of high-pressure brake lines5 and hoses to each wheel. At the wheel, the fluid pressure activates the brake caliper. This whole process is based on hydraulics, and it must be perfectly sealed.

Manufacturing and assembling these systems is incredibly difficult. Standard assembly equipment just doesn't have the precision required. For example, a critical step is the "braking force synchronization calibration11." This ensures all wheels brake with the correct, balanced force. The machinery for this is highly specialized. You typically only find it in established manufacturing hubs like the Yangtze River Delta or around Foshan in Guangdong. Small workshops simply can't meet these precision standards.

Core Brake System Components

| Component | Primary Function |

|---|---|

| Brake Pedal | The driver's input to start the braking process. |

| Brake Booster | Multiplies the force from the pedal for easier braking. |

| Master Cylinder | Converts mechanical force into hydraulic pressure2. |

| Brake Lines | Tubes that carry pressurized brake fluid10 to the wheels. |

| Brake Fluid | The liquid used to transfer pressure through the system. |

| Caliper/Wheel Cylinder | Uses hydraulic pressure2 to apply the friction material. |

| Pads/Shoes | The friction material that contacts the rotor/drum. |

| Rotor/Drum | The rotating component that the friction material clamps onto. |

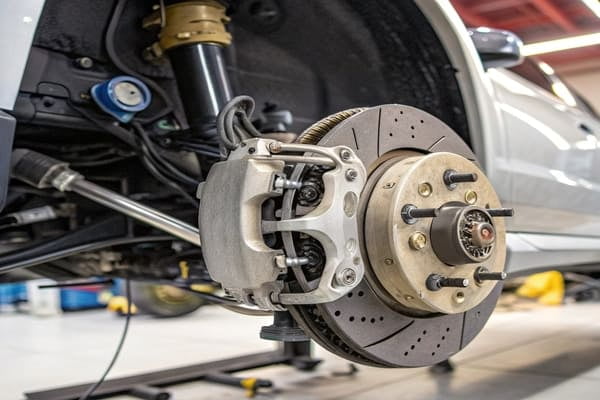

Which Brake Parts Belong to the Disc Brake System?

Most modern cars use disc brakes, but they have different parts than older drum brakes. Mixing them up during sourcing can be a costly and time-consuming mistake. Let's focus on the disc brake.

A disc brake system12m](https://shuipet.com/what-is-a-brake-shim-and-why-is-it-important-for-your-vehicle/)%%%FOOTNOTE_REF_1%%% uses a brake caliper, brake pads7, and a brake rotor. The caliper acts like a clamp. When you brake, hydraulic fluid pushes a piston inside the caliper, which squeezes the brake pads7 against the spinning rotor, stopping the car.

Let's dive a little deeper into the key parts of a disc brake setup. The brake rotor is the large metal disc that spins with the wheel. The brake caliper is mounted over the rotor. Inside the caliper are the brake pads7, which are blocks of friction material. When you hit the brakes, the caliper's piston pushes the inner brake pad against the rotor. This force also pulls the entire caliper body inward, pressing the outer brake pad against the other side of the rotor. This powerful clamping action creates immense friction and heat, which is what slows the car down.

Another challenge in manufacturing is testing the brake line's seal. During the testing procedure, the equipment has to stop. To perform the check, you have to open the line's interface. This makes it very difficult to maintain constant pressure and get an accurate reading. It's a technical problem that requires very specific solutions and equipment to overcome, ensuring there are absolutely no leaks in the final product. A tiny leak can lead to a total loss of braking power.

Disc Brakes vs. Drum Brakes

| Feature | Disc Brake System | Drum Brake System |

|---|---|---|

| Main Parts | Caliper, Pads, Rotor | Wheel Cylinder, Shoes, Drum |

| Mechanism | Caliper squeezes pads against a spinning disc. | Shoes push outward against the inside of a spinning drum. |

| Performance | Better heat dissipation, less prone to fade. | Can be less effective when hot, more complex. |

| Common Use | Front wheels on nearly all cars; all wheels on many. | Often found on the rear wheels of older or budget cars. |

What Does a Brake Pad Do and Why Does It Wear Out?

Brake pads are a common replacement part, which means they are a recurring expense. If you understand why they wear out, you can choose more durable and reliable options for your customers.

A brake pad is simply a block of friction material bonded to a steel backing plate. Its only job is to press against the rotor to create friction. It wears out because this process grinds away its surface over time, converting motion into heat.

The science is straightforward: to stop a moving car, you have to get rid of its kinetic energy. The brake system1 does this by converting that energy into thermal energy, or heat. The brake pad is the tool for this conversion. When it's pressed against the spinning rotor, the friction generates incredible heat, and the car slows down. This friction is a destructive force by nature. A tiny layer of the pad's material and the rotor's material is scraped away with every stop. Over thousands of miles, this adds up, and the pad becomes too thin to work safely.

I remember my first time producing a brake assembly13 for a European client. We were still learning, and after assembly, the parts had a noticeable "brake response lag." The braking force didn't engage as quickly as it should have. This was due to an issue in our "braking force synchronization calibration11" process, which is one of the hardest steps to perfect. I was worried, but the client put them on a city commuter car. They actually preferred the slightly softer, delayed engagement for smooth city driving. It was a lucky break, but it taught us a valuable lesson. We perfected our calibration process after that and never made that mistake again.

Brake Pad Material Comparison

| Material Type | Pros | Cons | Best For |

|---|---|---|---|

| Organic (NAO) | Quiet, less expensive, easy on rotors. | Wears faster, creates more dust, lower heat tolerance. | Daily commuting. |

| Ceramic | Very quiet, low dust, stable at high temps. | Most expensive, may feel less "bitey" than other types. | Luxury & performance. |

| Semi-Metallic | Excellent heat transfer, durable, strong bite. | Can be noisy, creates more dust, wears rotors faster. | Performance & heavy-duty. |

How Does a Brake Rotor Convert Speed into Stopping Power?

A brake rotor looks like a simple metal disc, but its design is critical. A poorly designed rotor can overheat and fail, so understanding its function is key to sourcing safe parts.

The brake rotor is the surface the pads clamp onto. It converts the wheel's rotational energy into heat through friction. Its most important job, besides providing that friction surface, is to dissipate that heat quickly and efficiently to prevent the brakes from failing.

Think of the brake rotor as a heat sink for the entire wheel. When the pads clamp down, temperatures can spike to hundreds of degrees in seconds. If that heat isn't managed, two bad things can happen. First, the brake pads7 can overheat and create a layer of gas between the pad and rotor, causing "brake fade14" where the pedal feels soft and the car doesn't stop well. Second, the extreme heat can warp or even crack the rotor itself, leading to total failure. This is why rotor design is so important.

Many rotors are not solid discs. Vented rotors have internal fins that create an air pump effect, pulling cool air through the middle to carry heat away. Some performance rotors have holes drilled through them or slots cut into their surface. Drilled holes help gases escape and improve cooling, while slots wipe the pad surface clean, ensuring a good contact patch. The choice depends entirely on the vehicle's intended use, from daily driving to heavy-duty towing or track racing. Each design is a balance between cooling, structural integrity, and pad wear.

Brake Rotor Type Comparison

| Rotor Type | Primary Benefit | Common Application |

|---|---|---|

| Solid | Simple, inexpensive to manufacture. | Rear brakes on small, light cars. |

| Vented | Superior cooling for better performance. | Front brakes on almost all modern cars. |

| Drilled | Helps vent hot gases, improves wet braking. | Performance and racing cars. |

| Slotted | Cleans pad surface, resists brake fade14. | Performance driving, trucks, and towing. |

Conclusion

A car's brake system1 uses hydraulic force to press pads against rotors. Understanding how each part works is the key to sourcing reliable and high-performance components for your market.

Explore this resource to understand the essential functions and components of a car's brake system. ↩

Learn about the role of hydraulic pressure in braking efficiency and safety. ↩

Discover the types of friction materials used in brake pads and their importance. ↩

Discover the critical role of the master cylinder in converting force into hydraulic pressure. ↩

Understand the significance of brake lines in ensuring effective brake fluid transfer. ↩

Discover how calipers apply pressure to brake pads for effective stopping. ↩

Find out how brake pads function and factors that contribute to their wear. ↩

Explore the design and function of brake rotors in the braking process. ↩

Learn how a brake booster amplifies force for easier braking. ↩

Understand the role of brake fluid in transferring pressure within the brake system. ↩

Understand the importance of calibration in achieving balanced braking performance. ↩

Explore the key parts of a disc brake system and their functions. ↩

Discover the complexities and precision required in brake assembly manufacturing. ↩

Learn about brake fade and strategies to maintain effective braking performance. ↩