Seeing "carbon fiber" at a low price can be confusing. It is not just about looks; it is about performance and your brand's integrity. Let's explain what hydro dipped carbon truly is.

Hydro dipped carbon fiber is not real carbon fiber1. It is a decorative finish2 applied to a base material, like ABS plastic or metal, using a water-transfer printing process3. This technique creates the carbon fiber look without the structural properties or high cost of the genuine material.

Now that you know the basic difference, you are probably wondering what this means for manufacturing and your products. This distinction is critical, as it impacts everything from cost and production time to the final performance of the part. Let's break down exactly what this process involves and why it is so common in the automotive accessories industry4.

What Exactly Does “Hydro Dipped Carbon” Mean in Manufacturing Terms?

Does 'hydro dipped carbon' sound like a high-tech material? This term can be misleading for those new to the industry. In manufacturing, it simply means a specific decorative process, not a structural component.

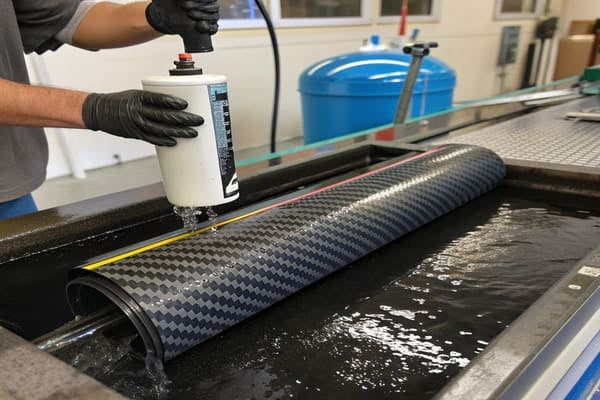

In manufacturing, 'hydro dipped carbon' refers to applying a printed graphic to a 3D object using water transfer printing5. A carbon fiber-patterned film is placed on water, an activator dissolves it into a liquid ink, and the part is dipped, wrapping the pattern around it.

From a production standpoint6, hydro dipping is a multi-stage surface coating process. It is all about aesthetics. The final part is a composite of layers, but not in the way real carbon fiber1 is. The core strength comes entirely from the substrate7, which is the base part we are decorating. This could be anything from an injection-molded ABS plastic mirror cover to a metal engine bay trim piece. The "carbon" part is just a microscopically thin layer of printed ink, protected by an automotive-grade clear coat8. The quality of the final product depends heavily on the machinery's precision and the operator's skill. High-quality work requires advanced equipment often found in specialized factories in industrial hubs like the Pearl River Delta or Suzhou. It is not something a small workshop can easily replicate to a high standard.

| Layer Description | Purpose in the Process |

|---|---|

| Substrate | The base part (e.g., ABS plastic, metal) that provides all structural integrity. |

| Primer/Adhesion Promoter | Ensures the base coat sticks properly to the substrate7. |

| Base Coat | A colored paint layer that provides the background for the pattern. |

| Hydrographic Ink Layer | The actual carbon fiber pattern transferred from the film. |

| Clear Coat | A protective top layer that provides UV resistance and a glossy finish. |

Is Hydro Dipped Carbon Fiber Structurally the Same as Real Carbon Fiber?

Do you need parts with true strength and low weight? Mistaking a decorative finish2 for a structural material is a critical error that can lead to product failure or misrepresenting your items to customers.

No, they are structurally completely different. Hydro dipped carbon fiber's strength comes from its base material, like plastic. The carbon look is just a thin decorative layer. Real carbon fiber is a composite material9 prized for its exceptional strength, stiffness, and light weight.

Let's get technical for a moment. Real carbon fiber is a fiber-reinforced polymer10. It consists of woven sheets of carbon fibers bonded together with a strong epoxy resin. This creates a single, unified material with an incredible strength-to-weight ratio. It is used in aerospace, motorsport, and high-performance vehicles for components that need to be both extremely strong and light, like a chassis or spoiler. A hydro dipped part, on the other hand, is usually a standard plastic or metal component. Its physical properties—strength, weight, and heat resistance—are determined entirely by that base material. The hydrographic film adds no structural value. It is purely cosmetic. Think of it like a very complex and durable paint job. You would not expect a coat of paint to make a plastic part as strong as steel, and the same logic applies here.

| Feature | Real Carbon Fiber | Hydro Dipped Part |

|---|---|---|

| Composition | Woven carbon fibers in a resin matrix. | A base material (e.g., plastic) with a printed ink layer. |

| Strength | Extremely high strength-to-weight ratio. | Depends entirely on the base material. |

| Weight | Very lightweight. | Weight of the base material. |

| Purpose | Structural and performance applications. | Purely cosmetic/decorative. |

| Cost | Very high due to materials and labor. | Low to moderate. |

How Does the Hydro Dipping Process Actually Work on Automotive Components?

Ever wonder how a flat pattern wraps perfectly around a complex part like a car's side mirror? Understanding this process is key to quality control and appreciating the skill involved in getting it right.

The process starts with preparing and priming the component. A PVA film with the carbon pattern is floated on water. An activator spray dissolves the film, leaving the ink pattern. The part is slowly dipped, and water pressure wraps the ink around it. Finally, it's rinsed and clear-coated.

The process is much harder than it looks. Every step is critical. First, the part must be perfectly clean and prepped with a primer and base coat. Any imperfection will show. The real challenge, however, comes during the dipping. The two hardest parts are getting the pattern to align correctly and ensuring the film adheres permanently. I remember my first project with a client from Pakistan. We had issues where the carbon pattern was peeling off after curing. This was due to poor adhesion treatment and problems with the fixture holding the part during dipping. The machine has to stop for treatment, which can compromise the film's bond if not handled perfectly. Luckily, the client actually liked the "distressed" look for their custom build, but it was a big lesson for us. This process requires incredible precision that only comes from high-end machinery and experienced technicians.

Key Production Stages

- Substrate Preparation: The part is sanded, cleaned, and a special adhesion promoter11 is applied.

- Base Coating: A paint color is applied which will show through the semi-transparent carbon pattern.

- Film Placement & Activation: The printed film is laid on the water's surface, and an activator chemical is sprayed to liquefy the ink.

- Dipping: The part is slowly and steadily immersed through the ink layer.

- Rinsing & Drying: The part is washed to remove any residue and then dried thoroughly.

- Clear Coating: A durable, automotive-grade clear coat8 is applied for protection and shine.

Why Do Manufacturers Use Hydro Dipping Instead of Solid Carbon Fiber?

If real carbon is so much better, why do we even use a look-alike? It might seem like we are just cutting corners, but there are solid manufacturing and business reasons behind this choice.

Manufacturers use hydro dipping primarily for two reasons: cost and versatility. It is vastly cheaper than manufacturing with real carbon fiber1. It also allows the carbon look to be applied to complex shapes12 and materials that are not suitable for carbon composite production.

The choice between real carbon fiber1 and hydro dipping comes down to the part's purpose. For a non-structural component like an interior dashboard trim, a gear shift knob, or an engine cover, the primary goal is visual appeal13. Using real carbon fiber1 for these parts would be massive overkill. The cost of materials, specialized molds, and labor-intensive layup process would make the final product prohibitively expensive for most markets. Hydro dipping provides a nearly identical look for a fraction of the cost. It also allows us to apply the finish to complex, injection-molded plastic parts that would be impossible or incredibly difficult to produce from real carbon fiber1. As an OEM/ODM supplier, we provide both options. For a client who needs a true performance wing, we use real carbon fiber1. For a client who wants to offer a stylish "carbon look" interior trim package, hydro dipping is the smart, cost-effective solution14.

| Factor | Real Carbon Fiber | Hydro Dipping |

|---|---|---|

| Unit Cost | Extremely High | Low |

| Best Application | Structural parts: chassis, spoilers, hoods. | Cosmetic parts: interior trim, mirror caps. |

| Production Speed | Slow, labor-intensive. | Fast, suitable for mass production15. |

| Shape Complexity | Limited by molding process. | Almost unlimited; can coat very complex shapes12. |

Conclusion

In short, hydro dipped carbon is a cosmetic finish, not a structural material. It provides the look without the cost, while real carbon fiber1 delivers performance. Always choose based on your product's application needs.

Discover the unique properties of real carbon fiber and why it's valued in high-performance applications. ↩

Discover the significance of decorative finishes in manufacturing and how they enhance product aesthetics. ↩

Learn about the innovative water-transfer printing process that creates stunning designs on various materials. ↩

Stay updated on the latest trends in the automotive accessories industry and how hydro dipping fits in. ↩

Explore the applications of water transfer printing in various industries beyond automotive. ↩

Gain insights into the production standpoint and its relevance in manufacturing processes. ↩

Learn about the role of substrates in manufacturing processes and their importance in product integrity. ↩

Find out how automotive-grade clear coats enhance the durability and appearance of automotive parts. ↩

Explore the definition and manufacturing processes of composite materials, including carbon fiber. ↩

Learn about fiber-reinforced polymers and their applications in various industries. ↩

Learn about the role of adhesion promoters in ensuring strong bonds in manufacturing. ↩

Discover the techniques used to manufacture complex shapes in the automotive industry. ↩

Understand the importance of visual appeal in product design and its influence on consumer choices. ↩

Explore various cost-effective solutions in manufacturing that enhance efficiency and reduce expenses. ↩

Learn about mass production techniques and their benefits in manufacturing industries. ↩