Industrial vacuum systems – and how?

Dust, debris, and toxins can shut down a production line fast. I’ve seen what happens when you try to use the wrong vacuum for the job—it’s costly and dangerous.

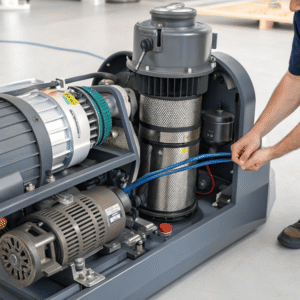

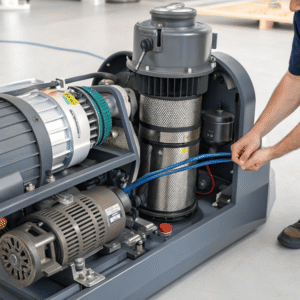

Industrial vacuum systems use high-powered motors[^1], strong filters, and robust collection tanks to remove waste, dust, and hazardous material from factory floors and machinery efficiently.

[^1]: Discover how high-powered motors contribute to the effectiveness of industrial vacuums, ensuring optimal waste removal.

use high-powered motors, strong filters, and robust collection tanks to remove waste, dust, and hazardous material from factory floors and machinery efficiently.

You can’t cut corners in an industrial setting. If you want a clean, safe workplace, the right vacuum system is the backbone of your maintenance plan. Let’s dive into the specifics that keep factories running.

How do industrial vacuum systems work?

Industrial sites throw out messes you can’t touch with regular shop vacs. Tackling those problems takes more than just size—it’s about the tech inside.

Industrial vacuum systems work by creating a strong suction force with heavy-duty motors. They use multiple-stage filters, including Industrial vacuum systems work by creating a strong suction force with heavy-duty motors. They use multiple-stage filters, including HEPA[^1] or cyclonic separation, to capture fine dust and hazardous materials. Waste is collected in reinforced tanks for easy and safe disposal.

[^1]: Explore this link to understand how HEPA filters enhance air quality and safety in industrial environments.

or cyclonic separation, to capture fine dust and hazardous materials. Waste is collected in reinforced tanks for easy and safe disposal.

Here’s what I’ve learned sorting out factory cleanups: The process starts with a high-powered motor that creates a low-pressure environment inside the vacuum. Debris and air rush in, moving through wide hoses that resist blockages. Inside the machine, a series of filters catches everything from large screws to invisible dust. HEPA or cyclone filtration is a must—the minute you try to cut costs here, dangerous particles escape. Tanks are built to handle corrosive materials and have safety latches to prevent spills. Some systems connect directly to equipment or production lines—automatically pulling dust from saws or CNC machines as they work. This hands-off collection means better air quality, less downtime, and a cleaner shop. If you ever see bags break or filters clog, you know right away why you need something built for punishment and long hours.

| Core Component | Purpose | Industrial Feature |

|---|---|---|

| Motor | Create suction | High-HP, continuous duty |

| Filtration System | Trap fine/volatile dust, toxins | HEPA/cyclonic, multi-stage |

| Collection Tank | Store wet/dry debris safely | Reinforced, high-capacity |

| Hoses & Attachments | Access hard-to-reach places/machines | Wide bore, anti-static |

| Safety Features | Protect user and facility | Shutoff, grounding, fireproof |

What is the best vacuum for industrial use?

There’s no tolerance for downtime when the stakes are this high. You need a solution that works for every shift, every day.

The best vacuum for industrial use is The best vacuum for industrial use is Nilfisk’s GD series for wet/dry jobs, and Pullman-Holt HEPA vacuums[^1] for hazardous dust. These models are engineered for high-volume, consistent operation, and safety certification.

[^1]: Discover why Pullman-Holt HEPA vacuums are essential for safety and efficiency in hazardous environments.

series for wet/dry jobs, and Pullman-Holt HEPA vacuums for hazardous dust. These models are engineered for high-volume, consistent operation, and safety certification.

When I help plants select equipment, Nilfisk always comes up first—they are built like tanks, handle both fine powders and heavy sludge, and are easy to service. Pullman-Holt dominates when safety is required. Their HEPA vacuums meet EPA and OSHA standards, so you don’t risk fines or unsafe air. What sets these apart from hardware-store shop vacs is their continuous-duty motors and ability to take non-stop abuse. You’ll find them in heavy industries, shipyards, and chemical plants. Each model is tailored—some units handle flammable or conductive dust, others are designed for food production or chemical resistance. The upfront cost is high, but you quickly recover your investment thanks to fewer breakdowns and much longer lifespans.

| Brand/Model | Application | Key Features | Approx. Cost |

|---|---|---|---|

| Nilfisk GD Series | Wet/dry, debris, powder | Continuous-duty, easy service | $1,000–$3,500 |

| Pullman-Holt HEPA | Hazardous, fine dust | Certified HEPA, OSHA compliant | $900–$2,500 |

| Ruwac | Heavy industry, custom | Custom options, explosion proof | $2,500+ |

If you need results day in and day out, investing in these systems pays for itself by preventing downtime and costly repairs.

What is the difference between industrial and commercial vacuums?

Looks can be deceiving—a big vacuum doesn’t mean it’s built for industrial work. Let me show what truly separates the two.

Industrial vacuums are engineered for relentless use, hazardous material collection, and large-scale debris, while commercial vacuums[^1] target everyday cleaning in offices or small businesses with lower duty cycles and simpler filtering systems.

[^1]: This resource will guide you on essential features of commercial vacuums, ensuring effective cleaning for your business.

are engineered for relentless use, hazardous material collection, and large-scale debris, while commercial vacuums target everyday cleaning in offices or small businesses with lower duty cycles and simpler filtering systems.

Here’s what I noticed working with both types: Commercial vacuums, like those you find in hotels or schools, are built for frequent but lighter cleaning. They handle dirt, crumbs, and about eight hours of work per day. They often use standard HEPA filters and medium-sized bags or bins. Industrial vacuums, however, run nonstop and suck up everything from concrete dust to hazardous chemicals. Their motors are meant for 24/7 use, often up to 20 horsepower, and they have features like anti-static hoses, explosion-proof housing, and bulk collection systems. Maintenance is different too—industrial machines are designed for quick service so no shift loses hours waiting on repairs. If a commercial model fails, it slows down a cleaning team. If an industrial vacuum fails, whole production lines can be forced to stop. Safety certifications are far stricter for industrial models because of the risks of flammable or toxic debris.

| Comparison Area | Commercial Vacuum | Industrial Vacuum |

|---|---|---|

| Duty Cycle | Intermittent, daily | Continuous, 24/7 |

| Material Handled | Dust, light debris | Toxic, conductive, heavy solids |

| Filtration | Standard HEPA | Multi-stage, HEPA/cyclone |

| Power | Up to 1-2 HP | 2–20 HP or more |

| Safety | Basic | Explosion proof, OSHA/EPA cert |

| Lifespan | 3–5 years typical | 10–20 years typical |

Choose commercial for maintenance teams, industrial for manufacturing and demanding cleanups.

Conclusion

Industrial vacuum systems give you the strength and safety for the toughest factory messes. Picking the right system keeps your operations safe and on track.