Industrial Vacuum Cleaners: What Makes Them Different and Which One Should You Choose?

Getting the right vacuum matters most when you need to move more than just dust at home. Heavy messes call for stronger solutions.

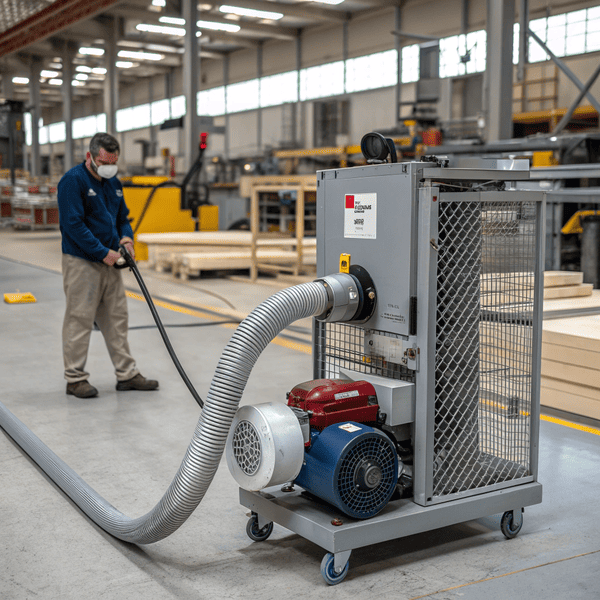

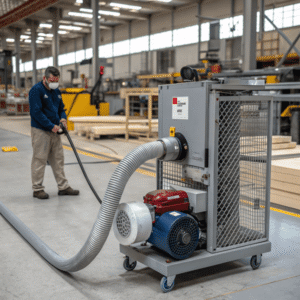

Industrial vacuum cleaners are built for heavy-duty jobs[^1]. They have stronger motors, larger capacities, and can handle tough debris that would break a standard commercial vacuum.

[^1]: This resource will provide insights into optimizing vacuum cleaner use for heavy-duty jobs, ensuring effective cleaning.

are built for heavy-duty jobs. They have stronger motors, larger capacities, and can handle tough debris that would break a standard commercial vacuum.

If you work in a factory, workshop, or construction area, waste cleanup is a big job. I often see people try to use regular commercial vacuums for heavy dirt, powders, or metal shavings. They give out quickly. Understanding the difference saves both time and money. Let me break down how industrial vacuums differ, what they’re called, and which models really get the job done.

What is the difference between industrial and commercial vacuums?

It is easy to confuse “industrial” with “commercial” on a sales tag, but knowing the difference is key.

Industrial vacuums are stronger, last longer, and take more abuse than commercial vacuums. They are designed for hazardous dust, heavy debris, and round-the-clock use.

Most Most commercial vacuums are for places like hotels, offices, or small workshops. They handle dirt, dust, and maybe light debris over several hours each day. Industrial vacuums[^1] go a step further. They need to keep up in places like factories, mines, or construction zones where debris can be metal, glass, wet concrete dust, or hazardous powders. In my experience, the filters and motors on industrial models last far longer and rarely clog or overheat.

[^1]: Explore this link to understand how Industrial vacuums enhance efficiency and safety in demanding environments.

are for places like hotels, offices, or small workshops. They handle dirt, dust, and maybe light debris over several hours each day. Industrial vacuums go a step further. They need to keep up in places like factories, mines, or construction zones where debris can be metal, glass, wet concrete dust, or hazardous powders. In my experience, the filters and motors on industrial models last far longer and rarely clog or overheat.

Here’s a breakdown to help you see the difference:

| Feature | Industrial Vacuum | Commercial Vacuum |

|---|---|---|

| Motor Power | High (heavy-duty, 2+ kW) | Medium (around 1 kW) |

| Duty Cycle | Continuous, 24/7 possible | Limited use (few hours/day) |

| Capacity | Large tanks (30-100+ liters) | Medium tanks (10-50 liters) |

| Debris Types | Wet, hazardous, heavy, sharp | Dry/wet, light debris |

| Filter System | HEPA, multi-stage, specialty | Standard, medium Grade |

| Construction | Rugged steel, chemical proof | Durable plastic/metal |

| Price | $$$$ (High) | $$-$$$ (Mid-high) |

What is an industrial vacuum called?

Industrial vacuums are sometimes known by other names, making it hard for buyers to search.

They are often called heavy-duty vacuum cleaners, shop vacs, dust extractors, or industrial dust collectors, depending on the industry and country.

Different job sites use their own words. In metal shops, I see “swarf vacuums” for collecting tiny metal pieces. On construction sites, workers ask for “On construction sites, workers ask for “HEPA dust extractors” to meet safety codes. Factory technicians usually refer to them as “industrial vacuum systems[^1]” or “central vacuum units” because they connect to pipes in the floor or ceiling

[^1]: Exploring industrial vacuum systems can help you learn about efficient dust control and improved air quality in various environments.

” to meet safety codes. Factory technicians usually refer to them as “industrial vacuum systems” or “central vacuum units” because they connect to pipes in the floor or ceiling. In North America, “shop vac” is a common name even though not all shop vacs are truly industrial grade.

It helps to know these names when searching for the right machine. For special environments, you’ll see terms like ATEX vacuum (for explosive dusts), slurry vacuum (for liquids), or pneumatic vacuum (air-powered for hazardous waste).

Common Names for Industrial Vacuum Cleaners

| Name | Typical Use | Notes |

|---|---|---|

| Heavy-duty Vacuum | General factories/warehouses | Broadest term, most common |

| Shop Vac | Worksites/garages | Not all “shop vacs” are industrial |

| Dust Extractor | Construction/woodworking | Specialized for fine particles |

| Swarf Vacuum | Metal fabrication | Handles metal shavings |

| Central Vac System | Large plants | Fixed installation |

What is the best industrial suction vacuum?

When you need the best industrial suction, you need a vacuum that is powerful, reliable, and safe for heavy-duty cleanup.

The top industrial suction vacuums are Nilfisk ATTIX, Delfin Industrial, and Ruwac, known for their high airflow, filtration, and durability on tough debris.

From my work with factories and CNC shops, the real standouts come from brands like Nilfisk, Delfin, Ruwac, Kärcher, and Pullman Ermator. The From my work with factories and CNC shops, the real standouts come from brands like Nilfisk, Delfin, Ruwac, Kärcher, and Pullman Ermator. The Nilfisk ATTIX series is a go-to for hazardous dust: it combines powerful suction, HEPA filtration[^1], and rugged construction

[^1]: Learn about HEPA filtration to see how it enhances air quality and safety in industrial settings.

is a go-to for hazardous dust: it combines powerful suction, HEPA filtration, and rugged construction. Delfin’s industrial vacuums are designed for continuous use and customized to handle anything from powders to large solid debris. Ruwac offers explosion-proof options for places with fire risks.

I always tell people to think about what they actually need—maximum airflow (measured in CFM), suction power (measured in kPa), and safe dust containment. For any machine, check if it meets your country’s safety codes, especially when handling combustible dusts.

Top Industrial Vacuum Models

| Model | Brand | Power | Best Use | Notes |

|---|---|---|---|---|

| ATTIX 965-21 SD | Nilfisk | Dual-motor, Wet/Dry | Hazardous dust, liquids | HEPA, robust build |

| DG 70 | Delfin | High-power | Powder, solids | Built for continuous use |

| DS 6 | Ruwac | Explosion-proof | Flammable dust | Custom filtration |

| IVS 100/40 | Kärcher | 4 kW | Heavy construction | German engineering |

| AERO 21-01 | Nilfisk | Portable | Workshops, cleaning | Affordable, High-value |

Conclusion

Industrial vacuum cleaners go beyond what commercial models can do. Choose one that matches your job needs and never worry about tough cleanups again.