How Does an Industrial Vacuum Work?

Dust and debris build up quickly in factories, risking efficiency, safety, and equipment damage. I’ve seen first-hand how a reliable industrial vacuum keeps production smooth and workspaces safe.

An industrial vacuum works by using a strong motor to create suction, pulling dust, dirt, or hazardous particles through durable hoses into a large An industrial vacuum[^1] works by using a strong motor to create suction, pulling dust, dirt, or hazardous particles through durable hoses into a large filtration tank, where contaminants are trapped for easy, safe disposal.

[^1]: Explore this link to understand the mechanics and benefits of industrial vacuums in various applications.

, where contaminants are trapped for easy, safe disposal.

Many people underestimate what makes an industrial vacuum different. Understanding how this equipment works can help you make smarter choices for your site’s needs. Let’s break it down.

How do industrial vacuum systems work?

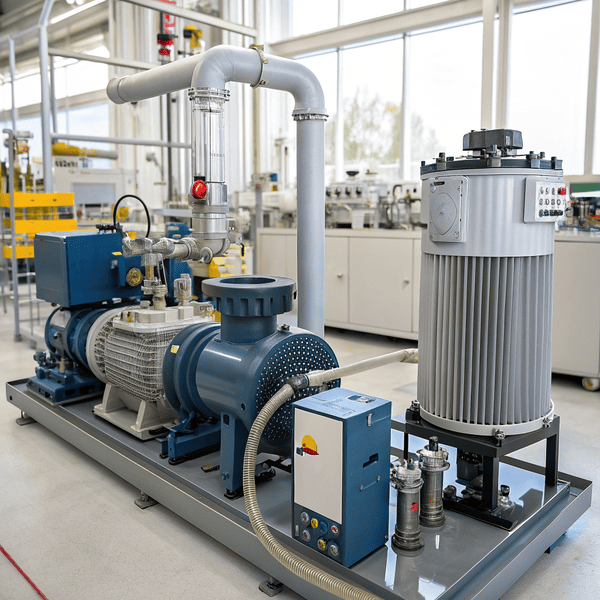

Industrial vacuum systems often look complex, but their action is simple when you see each part’s purpose.

Industrial vacuum systems work by generating high airflow and suction using heavy-duty motors, drawing materials through hoses and filters into storage containers, separating dust and hazardous substances from the cleaned air.

The system begins with a powerful electric or pneumatic motor that spins at high speed, dropping the pressure inside the main chamber. This pressure drop pulls debris through thick hoses. At the entry point, you’ll often find a pre-separator—a chamber that swirls dust and heavier debris down into a drum, which keeps most waste from reaching the At the entry point, you’ll often find a pre-separator[^1]—a chamber that swirls dust and heavier debris down into a drum, which keeps most waste from reaching the main filter

[^1]: Understanding pre-separators can enhance your knowledge of efficient dust collection and filtration systems.

. The main filtration unit then catches any fine particles, sometimes using multiple layers such as cyclone, cartridge, and HEPA filters. Clean air is exhausted back into the workspace, while all collected material stays secure in durable tanks designed for quick changeout or safety disposal. You can connect these systems directly to machines, or run them as central units for an entire facility. The whole setup is built for longevity, safe handling of dangerous dust, and low downtime.

| Part | Function |

|---|---|

| Motor (Electric/Pneumatic) | Creates suction force |

| Hose/Nozzle | Transfers debris from source to tank |

| Pre-Separator | Removes heavy debris |

| Main Filter | Catches fine, possibly hazardous dust |

| Exhaust | Returns clean air to workspace |

| Collection Tank | Stores all removed material |

How do vacuum systems work?

Vacuum systems power much more than cleaning—they also keep manufacturing and labs free of debris or contamination.

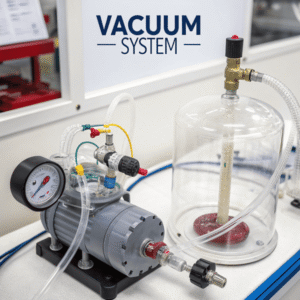

Vacuum systems work by reducing air pressure inside a chamber, so air, dust, or liquids move from higher-pressure environments into the low-pressure interior, carrying contaminants away for collection or disposal.

In simple terms, vacuums move material from one place to another by creating a pressure difference. The system includes a In simple terms, vacuums move material from one place to another by creating a pressure difference[^1]. The system includes a vacuum pump, which removes air from a sealed space. When you open the system’s inlet, the higher-pressure outside air (along with any dust, powder, or fluids in its path) rushes in to fill the vacuum

[^1]: Exploring pressure difference will deepen your knowledge of how vacuums function and their practical uses.

, which removes air from a sealed space. When you open the system’s inlet, the higher-pressure outside air (along with any dust, powder, or fluids in its path) rushes in to fill the vacuum. Piping, hoses, and valves control where the airflow goes. Filters or separators remove contaminants before the clean air is released or recirculated. I’ve assisted with vacuum installations in pharmaceutical labs, where these systems prevent cross-contamination and protect expensive equipment. Similar technology collects metal chips, liquid waste, or even dangerous gases in industrial settings. The principles remain the same, whether you’re cleaning a floor or running a scientific process.

| Component | Role |

|---|---|

| Vacuum Pump | Creates low pressure, enabling suction |

| Inlet/Nozzle | Access point for material intake |

| Piping/Valves | Directs airflow |

| Filtration | Separates contaminants from the air |

| Exhaust | Vents clean air or collects other materials |

How does a vacuum work step by step?

Watching a vacuum operate can seem like magic, but it follows basic physical laws. I get asked this a lot by new staff during equipment walkthroughs.

A vacuum works by: 1) turning on the motor to create suction, 2) using the hose or inlet to draw in debris, 3) passing debris into a filter, 4) trapping dirt in a A vacuum works by: 1) turning on the motor to create suction[^1], 2) using the hose or inlet to draw in debris, 3) passing debris into a filter, 4) trapping dirt in a collection tank, 5) releasing clean air.

[^1]: Understanding suction is crucial for optimizing vacuum performance and efficiency.

, 5) releasing clean air.

Here’s the process explained:

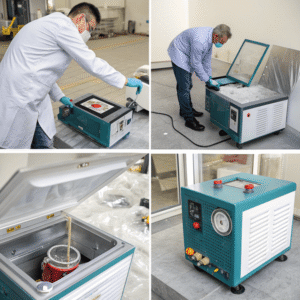

- Power Up – You flip the switch and the vacuum’s motor activates, spinning a fan or compressor rapidly.

- Suction Creation – The spinning motion lowers air pressure inside the vacuum’s body. Higher-pressure air from outside tries to move into the low-pressure space.

- Debris Ingestion – As the inlet hose or nozzle touches dirt or dust, the outside air—and whatever it carries—gets sucked in.

- Filtration – This moving air passes through pre-filters and main filters (cartridge, bag, HEPA), separating dust, lint, or hazardous particles from the airflow.

- Collection – The filters capture dirt, which falls into a sealed tank or bag for later disposal.

- Exhaust – The now-clean air leaves the system, recirculated into the workspace or vented safely outdoors, depending on the unit’s setup.

- Disposal – When the tank or bag is full, you detach and empty it, following proper safety steps if the debris is hazardous.

This step-by-step logic is the same for industrial and commercial vacuums, though larger systems have multiple filters, automatic cleanout, and custom disposal options. Following these simple steps helps operators, new and old, get better results.

| Step | Action | Purpose |

|---|---|---|

| 1. Power On | Start the motor | Initiates suction |

| 2. Suction | Motor lowers pressure | Creates air movement |

| 3. Intake | Draws in debris | Cleans target surface |

| 4. Filtration | Removes particles | Ensures only clean air exits |

| 5. Collection | Debris stored in tank/bag | Preps for disposal |

| 6. Exhaust | Releases clean air | Maintains safe environment |

| 7. Disposal | Empty tanks as needed | Safe waste handling |

Conclusion

Industrial vacuums use strong motors, filtration, and smart design to protect workers and keep workspaces clean—step by step, they create safer, more productive industries.