Struggling with inconsistent auto parts? A tiny error can cause huge problems. High-precision CNC machining1 is the answer, but the process is more complex than you think.

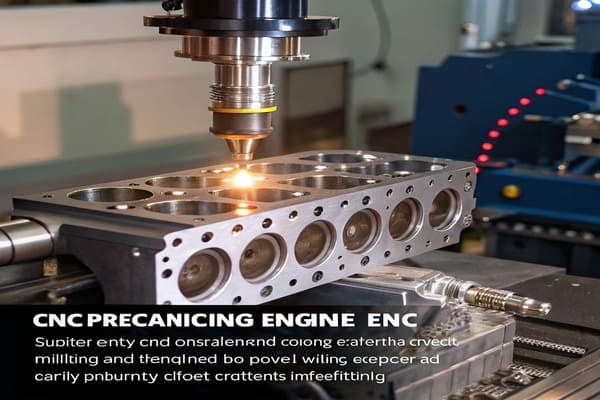

Automotive CNC machines use computer-controlled tools to cut, mill, and shape metal blocks into precise parts like engine components2 and brake systems3. The process involves programming a digital design, selecting the right tools, and executing multi-stage operations to achieve micron-level accuracy4 and perfect repeatability.

That's the high-level view, but the details are what separate a reliable part from a faulty one. The term "automotive CNC machine" itself can be misleading. To really understand the process, we need to break down what it means and why it's so critical for making parts you can trust.

What Do Engineers and Buyers Really Mean When They Search for “Automotive CNC Machine”?

Confused by the term "automotive CNC machine"? You might be looking for a parts supplier, not the machine itself. Let's clarify what buyers and engineers actually need.

When engineers and buyers search for "automotive CNC machine," they usually mean the service of manufacturing parts using these machines. They are looking for a supplier with the right equipment and the expertise to produce components to their exact specifications, not to buy the machine itself.

When you search for this term, you are looking for a manufacturing partner, not a piece of equipment to put in your own facility. It’s a search for a capability, a service that can turn your digital design into a physical, high-precision5 component. This is a critical distinction because the machine is just one part of the equation. The operator's skill, the quality control process6, and the factory's experience are just as important. For example, a small workshop might have a basic 3-axis CNC machine, but it can't handle the complex shapes of a modern engine block7. For that, you need a 5-axis machine8 and a team that knows how to program it. This is why the best suppliers are often found in industrial hubs like China's Yangtze River Delta or around Dongguan. These factories have invested in the advanced technology and skilled labor necessary for high-precision5 automotive work.

Sourcing a Service vs. Buying a Machine

| Aspect | Sourcing a Manufacturing Service | Buying a CNC Machine |

|---|---|---|

| Goal | Get finished, high-quality auto parts. | Own the equipment for in-house production. |

| Expertise Needed | Product design and specifications. | Machine operation, programming, and maintenance. |

| Focus | Finding a reliable supplier with proven capabilities. | Finding the right hardware for your needs. |

| Typical User | Auto brands, distributors, importers. | Large-scale manufacturers or specialized workshops. |

Why Are CNC Machines Essential in Modern Automotive Manufacturing?

Old manufacturing methods are too slow and inaccurate for today's cars. This leads to poor quality and safety risks. CNC machining1 is the solution for modern automotive production.

CNC machines are essential because they guarantee consistency and tight tolerances that are impossible to achieve manually. They allow for the mass production of complex, identical parts, which is critical for vehicle safety, fuel efficiency, and overall performance. This repeatability also reduces waste and lowers costs.

The core value of CNC machining1 is its incredible precision and repeatability. A human operator, no matter how skilled, cannot make two complex parts exactly the same. A CNC machine can produce thousands of them, each a perfect clone of the last, with tolerances measured in microns. This consistency is not a luxury; it's a requirement for modern vehicles. It ensures that every part fits perfectly, performs reliably, and meets safety standards.

I learned this lesson the hard way early in my career. We were working on a project for a client from Pakistan, and the parts we produced had a noticeable "dimensional deviation9." The tolerances were off. I was very worried, but the client was building a custom-modified car, and the slightly different dimensions actually fit his unique setup perfectly. We got lucky. That experience taught me that for standard production, perfect precision is non-negotiable. We immediately upgraded our quality control to ensure it never happened again.

Manual Machining vs. CNC Machining

| Feature | Manual Machining | CNC Machining |

|---|---|---|

| Precision | Low to moderate; dependent on operator skill. | Extremely high; micron-level accuracy4. |

| Repeatability | Poor; each part is slightly different. | Perfect; every part is virtually identical. |

| Complexity | Limited to simpler shapes and designs. | Can produce highly complex and intricate geometries. |

| Speed | Slow; not suitable for mass production. | Fast and efficient; ideal for large volumes. |

| Cost | High labor cost per part. | Lower cost per part at scale. |

Which Automotive Parts Rely Most on CNC Machining for Accuracy and Safety?

Do all car parts need extreme precision? No, but for some, it is critical for safety. Using a low-quality part in these systems is a dangerous risk. Let's list the non-negotiable components.

Safety-critical parts like brake calipers, suspension components, steering knuckles, and engine block7s rely heavily on CNC machining1. The precise tolerances ensure proper fit and function, directly impacting vehicle control and reliability. Transmission components and cylinder heads also require this accuracy for performance.

Not every piece of plastic trim in a car needs to be machined to a micron. But for the components that keep you safe on the road, there is no room for error. These parts form the core of the vehicle's mechanical systems, and their failure can be catastrophic. CNC machining1 is the only way to manufacture these parts with the required level of quality and consistency. For example, a brake caliper must have perfectly parallel surfaces to apply even pressure to the brake pads. A suspension control arm must have its mounting points in the exact right place to maintain proper wheel alignment. An engine block7 needs perfectly flat surfaces and round cylinders to contain the immense pressures of combustion. In these applications, precision is another word for safety. It's the silent, invisible feature that ensures your car behaves as expected every time you turn the wheel or press the brake pedal.

Key Automotive Systems Requiring CNC Precision

| Component Group | Key CNC-Machined Parts | Why Precision is Critical |

|---|---|---|

| Brake System | Calipers, Rotors, Brackets | Ensures even braking force, prevents vibration, and guarantees safety. |

| Suspension System | Control Arms, Steering Knuckles | Maintains correct wheel alignment, ensuring stable handling and control. |

| Engine & Drivetrain | Cylinder Heads, Engine Blocks, Transmission Cases | Guarantees proper sealing, efficient combustion, and smooth power delivery. |

How Does CNC Machining Improve Engine and Drivetrain Performance?

Want to boost engine performance and efficiency? Standard parts often fall short. CNC machining1 is the key to unlocking hidden power and reliability at the manufacturing level.

CNC machining1 improves performance by creating perfectly balanced rotating parts like crankshafts, reducing vibration. It allows for porting cylinder heads10 for better airflow and ensures engine block7 surfaces are perfectly flat for a superior seal, increasing both power and efficiency.

CNC machining1 takes engine building from an assembly process to a science. It allows for improvements that are impossible to achieve otherwise. For example, we can use a 5-axis CNC mill to reshape the intake and exhaust ports inside a cylinder head. This process, called "porting," smooths out the airflow, allowing the engine to breathe better and produce more power. We can also machine an engine block7's top surface, a process called "decking11," to make it perfectly flat. This ensures the head gasket creates a perfect seal, which is critical for high-compression or turbocharged engines.

However, this level of precision is incredibly difficult to achieve. The hardest part is what we call "precision dimensional milling12," where the machine has to remove material with incredible accuracy. Another major challenge is "precise tool speed control." To get the perfect surface finish, you need to adjust the cutting speed13. This often requires stopping the machine and opening the parameter panel. This interruption can affect the stability of the process and the final quality. It takes highly advanced machines and extremely skilled technicians14 to master these techniques and unlock an engine's true potential.

Conclusion

CNC machining1 is not just about cutting metal. It's the essential process ensuring the safety, performance, and reliability of modern vehicles through unmatched precision and repeatability.

Explore this link to understand the fundamentals of CNC machining and its critical role in automotive production. ↩

Find out how CNC machining contributes to the production of essential engine components. ↩

Understand the impact of CNC machining on the performance and safety of brake systems. ↩

Explore the significance of micron-level accuracy in manufacturing automotive parts. ↩

Discover why high-precision machining is vital for safety and performance in vehicles. ↩

Learn about the quality control measures that ensure precision in CNC machining. ↩

Discover why precision is crucial in the manufacturing of engine blocks. ↩

Discover the benefits of using a 5-axis CNC machine for complex automotive parts. ↩

Learn about dimensional deviation and its implications in automotive part manufacturing. ↩

Learn how porting cylinder heads enhances engine performance through CNC machining. ↩

Understand the decking process and its importance in achieving a perfect engine seal. ↩

Explore the concept of precision dimensional milling and its challenges in automotive manufacturing. ↩

Learn about the relationship between cutting speed and the quality of CNC machined parts. ↩

Discover the importance of skilled technicians in achieving high-quality CNC machining results. ↩