Hi-Vac Industrial Vacuum Systems

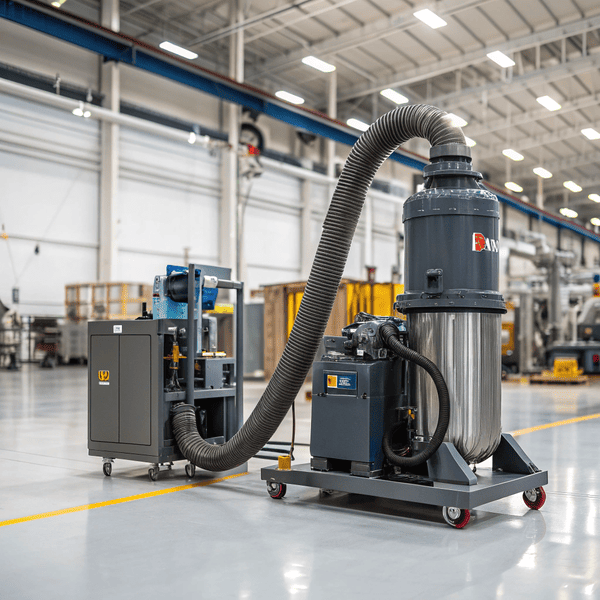

Factories and plants often deal with debris that ordinary vacuums can’t touch. I’ve seen how Hi-Vac systems transform these messy spaces into clean, safe workplaces.

A A Hi-Vac system is a powerful industrial vacuum[^1] setup using heavy-duty motors, strong hoses, and advanced filtration to clear large-scale debris, dust, and hazardous materials from factories, warehouses, and plants.

[^1]: Discover the advantages of industrial vacuums for efficient cleaning and safety in various industries.

is a powerful industrial vacuum setup using heavy-duty motors, strong hoses, and advanced filtration to clear large-scale debris, dust, and hazardous materials from factories, warehouses, and plants.

Big cleaning challenges require big solutions. Let's get clear on what makes Hi-Vac systems special and why they matter so much in serious industrial settings.

What is a hi-vac system?

Everyday equipment cannot keep up with endless debris and dust. Hi-Vac systems were built for these jobs.

A Hi-Vac system is anA Hi-Vac system[^1] is an industrial vacuum that uses high-horsepower motors, robust steel tanks, and wide hoses to clear heavy debris, dust, and hazardous waste from large workspaces.

[^1]: Explore this link to understand the functionality and benefits of Hi-Vac systems in industrial applications.

that uses high-horsepower motors, robust steel tanks, and wide hoses to clear heavy debris, dust, and hazardous waste from large workspaces.

Hi-Vac systems start with powerful motors that draw in material at very high speed through extra-large hoses. They’re designed to run around the clock and move everything from metal shavings to concrete dust. Tanks are built from Tanks are built fromTanks are built from reinforced steel to hold large volumes of waste. The filtration system is multi-stage, often including cyclone separators and HEPA filters[^1], so nothing hazardous escapes into the workspace

[^1]: Learn about HEPA filters and their effectiveness in removing hazardous particles from the air.

to hold large volumes of waste. The filtration system is multi-stage, often including cyclone separators and HEPA filters, so nothing hazardous escapes into the workspace to hold large volumes of waste. The filtration system is multi-stage, often including cyclone separators and HEPA filters, so nothing hazardous escapes into the workspace. Using one in a factory feels very different from using a regular shop vacuum—the suction is stronger, hoses resist kinks, and the machine holds up for years. You can connect the system to production equipment, run it through multiple rooms, or mount it for mobile jobs. This flexibility lets you clean up everything from spilled grain to dangerous toxins safely and quickly.

| Feature | Hi-Vac System | Regular Shop Vac |

|---|---|---|

| Motor Power | High horsepower (5–20 HP) | Low/mid horsepower |

| Application | Bulk, hazardous debris | Light dust, crumbs |

| Filtration | Multi-stage, HEPA, cyclone | Basic filter |

| Tank Capacity | Extra-large steel | Small plastic |

| Usage | Continuous, large spaces | Intermittent, small areas |

Which is the best industrial vacuum cleaner?

Operators need a vacuum they can depend on for relentless cleaning, without breakdowns or weak suction.

The best industrial vacuum cleaner is the Ruwac Red Line or Hi-Vac’s own HVS Series. Both models reliably move heavy dust, hazardous waste, and bulk material, with proven safety and long operational life.

Ruwac Red Line stands out for its Ruwac Red Line stands out for its custom filtration, tough steel build, and strong motors. Hi-Vac HVS Series[^1] excels in moving large amounts of waste quickly over long distances and can be tailored to suit specific factory needs

[^1]: Discover the unique features of the Hi-Vac HVS Series that optimize waste movement and management in industrial settings.

, tough steel build, and strong motors. Hi-Vac HVS Series excels in moving large amounts of waste quickly over long distances and can be tailored to suit specific factory needs. Both brands offer OSHA-compliant filtration and are designed to handle fine powders, liquids, and combustible dust safely. You find these machines on production floors, in mining, and anywhere cleanup cannot afford delays. Their costs are higher than off-the-shelf shop vacs, but their longevity and ability to withstand constant use more than make up for it. I have seen companies cut their maintenance times and improve worker safety by switching to these top industrial vacuums, year after year.

| Brand/Model | Motor Strength | Filtration | Durability | Application |

|---|---|---|---|---|

| Ruwac Red Line | High | HEPA/cyclone | 10–20 years | Dust, hazardous waste |

| Hi-Vac HVS Series | Very high | Multi-stage | 10+ years | Bulk debris |

| Pullman-Holt HEPA | High | True HEPA | 8–15 years | Fine dust, toxins |

What is considered a high vacuum?

Vacuum levels make or break how effective your cleaning system is. Here’s how high vacuum truly compares.

A high vacuum in industrial cleaning refers to strong suction creating a A high vacuum[^1] in industrial cleaning refers to strong suction creating a low-pressure environment, usually above 85 inches water lift or under 0.1 mbar, which is vital for moving heavy and hazardous materials.

[^1]: Understanding high vacuum is crucial for effective industrial cleaning, ensuring safety and efficiency in handling materials.

, usually above 85 inches water lift or under 0.1 mbar, which is vital for moving heavy and hazardous materials.

Industrial vacuums are rated by their suction power, often measured in “inches of water lift” or air pressure (mbar/kPa). High vacuum systems generate powerful suction that can pull up heavy metals, moist slurries, and thick powders. For comparison, standard wet/dry vacs operate with 50–60 inches of water lift; high vacuums exceed 85 inches. This capability means you can remove waste from long distances, pull material from deep pits, or maintain clean air in hazardous zones. Facilities with toxic, combustible, or high-volume debris depend on high vacuum for compliance and efficiency. I’ve seen regulatory teams focus on vacuum ratings when approving new equipment. Upgrading to a high vacuum model often means safer operations, fewer filter clogs, and faster cleanup on every shift.

| Rating Level | Inches of Water Lift | Pressure (mbar) | Main Use Case |

|---|---|---|---|

| Low Vacuum | 20–40 | >500 | Light debris, small areas |

| Medium Vacuum | 40–85 | 100–500 | General cleaning |

| High Vacuum | 85+ | <100 | Industrial, hazardous jobs |

Conclusion

Hi-Vac industrial vacuum systems deliver top performance, safety, and reliability for the toughest factory and plant cleaning jobs—saving time and protecting workers.