Different Types of Industrial Vacuum Systems?

Factories and workshops need specialized cleaning equipment for safety and efficiency. I’ve watched businesses thrive by picking the right industrial vacuum systems for their unique needs.

Industrial vacuum systems come in many types, including vacuum pumps, portable vacuums, and central vacuum units. Each system has key differences in power, filtration, and application for specific Industrial vacuum systems[^1] come in many types, including vacuum pumps, portable vacuums, and central vacuum units. Each system has key differences in power, filtration, and application for specific industrial environments.

[^1]: Explore this link to understand the various vacuum systems and their specific applications in industrial settings.

.

Choosing the right vacuum system for your worksite can be confusing. I’ll break down the major categories so you can match equipment with your cleaning goals.

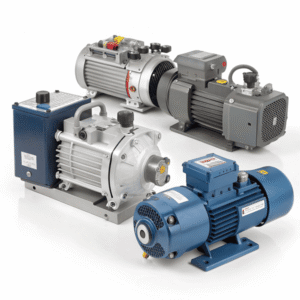

What are the different types of industrial vacuum pumps?

Industrial vacuum pumps deliver the muscle behind vacuum systems, but their operating principles differ, and each is suited to different jobs.

The main types of industrial vacuum pumps areThe main types of industrial vacuum pumps[^1] are rotary vane, diaphragm, liquid ring, claw, screw, and piston. These pump types vary in vacuum level, efficiency, and application.

[^1]: Explore this link to understand the various types of industrial vacuum pumps and their specific applications.

, diaphragm, liquid ring, claw, screw, and piston. These pump types vary in vacuum level, efficiency, and application.

After years helping shops select the best pumps, I’ve learned that rotary vane pumps are great for general applications, offering both rough and fine vacuum levels. Diaphragm pumps do well in chemical or clean rooms because they do not contaminate air. Liquid ring pumps are perfect for handling wet, dusty, or dangerous gases. Claw and screw pumps are known for their oil-free operation and continuous use. Piston pumps create deep vacuums for heavy-duty work but need more maintenance. Ask your supplier about maximum pressure, oil needs, and service intervals. Matching the pump to your facility’s cleanup job can improve reliability and keep running costs lower.

| Pump Type | Vacuum Level | Key Advantage | Best Used For |

|---|---|---|---|

| Rotary Vane | Rough–Fine | Versatile | Packaging, drying |

| Diaphragm | Low–Medium | Clean air | Lab, pharmaceuticals |

| Liquid Ring | Medium | Wet gases/dust | Chemical, food, waste |

| Claw/Screw | Medium–High | Oil free, quiet | Industrial, electronics |

| Piston | High/Deep | Powerful suction | Heavy-duty, metallurgy |

What are different types of vacuums?

Not all vacuums are made alike—choosing based only on price can create big cleaning problems down the road.

Industrial vacuums include wet-dry models,Industrial vacuums include wet-dry models, HEPA-filter vacuums, explosion-proof units[^1], and portable vacuums. Each type is designed to handle different kinds of debris and meet specific safety requirements.

[^1]: Learn about explosion-proof units and their critical role in ensuring safety in hazardous environments, protecting both workers and equipment.

, explosion-proof units, and portable vacuums. Each type is designed to handle different kinds of debris and meet specific safety requirements.

Wet-dry vacuums are used on job sites and in shops that deal with liquids and mixed debris. HEPA vacuums protect workers by filtering out fine or hazardous dust—essential in pharmaceutical, electronics, and mold remediation. Explosion-proof vacuums include non-sparking motors and antistatic hoses for cleaning environments with flammable dust or gases, such as grain processing or chemical plants. Portable industrial vacuums are lightweight, easy to move around, and fit for quick cleanups in smaller spaces. Picking the wrong vacuum makes cleaning slower and increases safety risks. Get advice based on the material you handle, the space you clean, and the safety codes you must meet before buying.

| Type | Main Purpose | Pros | Popular Settings |

|---|---|---|---|

| Wet/Dry Vacuum | Liquids/solids | Versatile, easy to maintain | Construction, workshops |

| HEPA Vacuum | Fine/toxic dust | Protects air, OSHA compliant | Pharma, electronics, labs |

| Explosion-Proof | Flammable zones | Safe, certified | Chemicals, food, grains |

| Portable Vacuum | Quick cleanup | Easy to move, compact | Offices, small factories |

What are the different types of central vacuum systems?

Central vacuum systems offer a permanent solution for large sites, letting workers clean more space with less time and effort.

Central vacuum systems include single-stage, multi-stage, and custom modular setups. They are used for dust collection[^1], bulk material handling, and hazardous waste in factories and big buildings.

[^1]: Learn about the mechanisms of dust collection in industries to enhance your knowledge on effective waste management solutions.

include single-stage, multi-stage, and custom modular setups. They are used for dust collection, bulk material handling, and hazardous waste in factories and big buildings.

Single-stage central vacuum systems have one big motor and filtration unit connected by pipes through the facility. These are easy to maintain and suit small-to-medium sites. Multi-stage systems add extra motors, filtration, and remote controls, boosting cleaning speed and coverage. Custom modular systems fit the most complex facilities, integrating special filters, explosion-proof options, and digital monitoring. I’ve helped clients retrofit modular central vacuums for tough jobs, like composite manufacturing and mining cleanup. Central systems can run around the clock and cover multiple workstations. They may demand a higher investment but reduce labor and downtime over ten years. Always consider how future expansions and new materials might change your vacuum needs.

| System Type | Power Source | Best For | Features/Options |

|---|---|---|---|

| Single-Stage | 1 motor/centrifugal | Small/medium sites | Basic filtration |

| Multi-Stage | Multiple motors | Large buildings | Multiple filter options |

| Modular/Custom | Variable | Special requirements | HEPA, explosion-proof |

Conclusion

There are many types of industrial vacuum systems. Understanding each helps you make smarter choices for cleaner, safer, and more efficient workplaces.