Worried about your car's stopping power? Choosing the right rotors can be confusing. We will help you understand if Bosch is the top choice for your vehicle's safety.

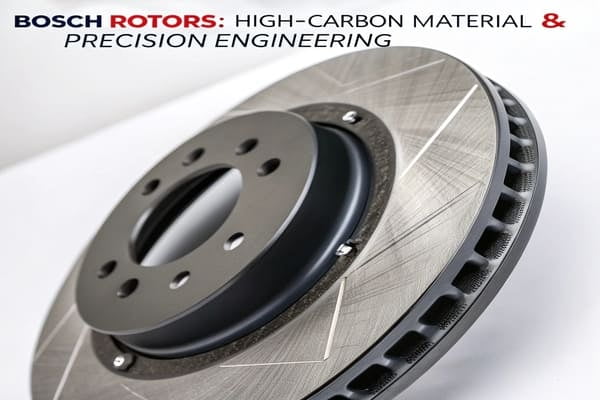

Bosch rotors1 are often considered a top choice due to their high-carbon material2 and precision engineering3, which deliver excellent heat management4 and durability. They are a benchmark for quality, but the "best" choice ultimately depends on your specific vehicle, driving style, and budget.

But what really makes them so special? It is not just about the brand name printed on the box. The real story is hidden in the manufacturing process, something I know a lot about from my years in this industry. Let's look behind the scenes to see if they truly live up to the hype and are worth your money.

Is Bosch a Manufacturer or Just a Brand Owner?

Confused about who actually makes the parts you buy? Many famous brands don't make their own products. We will clarify Bosch's role to help you understand what you're buying.

Bosch is both a major global manufacturer and a brand owner. They operate their own factories but also partner with certified OEM suppliers5 like us to produce parts to their strict specifications. This dual approach ensures consistent quality across their entire product line.

In the auto parts world, it is very common for a brand to not make every single part themselves. This is known as the OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer) model. As a factory owner who works with global brands, I can tell you how this works. A major brand like Bosch has a reputation to protect. They can't just put their name on any product.

The OEM Partnership Model

When Bosch decides to work with an outside factory, the process is incredibly strict. They don't just send us a drawing and hope for the best. Their engineers visit our facility. They audit our production lines, check our quality control6 systems, and certify the raw materials we use. We have to prove that we can meet their standards, which are often even higher than the original car manufacturer's specs. The part may be made in our factory, but it is made the "Bosch way." This ensures that whether the rotor comes from a Bosch-owned plant in Germany or a certified partner in Asia, the quality is identical.

Bosch's Quality Control System

The brand's name is on the line with every part sold. Because of this, their quality control6 is everywhere. It starts with the raw materials and continues through casting, machining, and final inspection. This system is the same everywhere.

| Aspect | In-House Bosch Factory | Certified OEM Partner |

|---|---|---|

| Engineering Specs | Set by Bosch Global | Provided by Bosch Global |

| Material Quality | Certified by Bosch | Certified by Bosch |

| QC Process | Audited by Bosch | Audited by Bosch |

| Final Product | Meets Bosch's global standard | Meets Bosch's global standard |

What Makes Bosch Rotors Different from Other Brands?

Aren't all brake rotors just round pieces of metal? The small details can create a huge difference in stopping power and safety. We will show you what sets Bosch apart.

Bosch rotors1 stand out because of their specific high-carbon material2 and extremely precise manufacturing. This combination leads to better heat control, less vibration, and quieter braking. Their engineering focuses on matching or exceeding original equipment (OE) fit and performance, making them a reliable choice.

From my experience as a manufacturer, producing a rotor to Bosch's standards is incredibly difficult. It requires specialized machinery and deep expertise. Two areas are especially challenging: the material composition and the machining process7.

The Challenge of High-Carbon Smelting

The secret to a great rotor starts with the metal itself. Bosch rotors1 use a high-carbon cast iron8 formula. This isn't your standard iron. The higher carbon content helps the rotor absorb and get rid of heat more effectively, which prevents brake fade9 and reduces the risk of the rotor warping. However, controlling the carbon content during the smelting process is extremely difficult. It requires advanced machinery that can manage the molten metal with incredible precision. Most small workshops simply don't have this capability. The specialized foundries that can do this are concentrated in a few industrial areas, like the Yangtze River Delta region in China.

Precision in Every Detail

The next challenge is machining. For example, drilling the ventilation holes inside the rotor requires laser precision. The machine has to stop for each hole, and the jig holding the rotor in place has to open and close. This action can easily ruin the rotor's flatness. Maintaining perfect flatness is critical to prevent steering wheel shimmy10 and brake pedal pulsation.

I remember the first time my factory produced a batch of high-performance rotors for a European client. Our process wasn't perfect yet, and the rotors developed tiny "surface heat cracks" after machining. I was worried the client would reject the whole order. To my surprise, they loved it. Their customers used the cars on the track, and they felt the cracks gave the rotors a more aggressive, race-ready look. It was a lucky break, and a valuable lesson. We perfected our process right after, but it shows how demanding this level of manufacturing really is.

| Feature | High-Carbon Rotors (Bosch) | Standard G3000 Iron Rotors |

|---|---|---|

| Heat Dissipation | Excellent | Good |

| Vibration/Noise | Very Low | Low to Moderate |

| Warp Resistance | High | Moderate |

| Manufacturing Cost | Higher | Lower |

Are Bosch Rotors Made in the USA or Imported?

Want to know where your parts are really from? The country of origin for auto parts can be a complex topic. We will explain where Bosch rotors1 are actually produced.

Bosch is a global company, so their rotors are manufactured in various countries worldwide, including China, Germany, and Mexico. The country of origin does not determine the quality. Bosch's strict global engineering standards and quality control6 are what ensure consistent performance everywhere.

Many people want to buy parts made in a specific country, like the USA. But for a global company like Bosch, it's not that simple. They have a massive supply chain that spans the entire world. A rotor sold in America might be cast in China, machined in Mexico, and packaged in the United States. This is the reality of modern manufacturing.

A Global Manufacturing Footprint

As a manufacturer based in China, I often see a bias against parts made here. People assume "Made in China" means low quality. This is an outdated idea. Today, the most advanced manufacturing technology11 for certain products, like the high-precision casting needed for Bosch-level rotors, is located here. The brands know this. They come to us and other factories in our region because we have the equipment and the skilled labor to meet their quality demands. The location is not what matters; the investment in technology and quality control6 is what counts.

Why "Made In" Doesn't Tell the Whole Story

You should not judge a part by the country printed on the box. Instead, judge it by the brand that stands behind it. Bosch puts its reputation on every single rotor, no matter where it was made. They enforce the same material specifications12, the same machining tolerances, and the same final inspection processes in every factory, whether it's their own or a partner's. The quality comes from the brand's system, not the factory's address.

| Factor Determining Quality | Importance |

|---|---|

| Material Specification | High |

| Machining Tolerance | High |

| Quality Control Process | High |

| Country of Origin | Low |

How Do Bosch Rotors Compare to PowerStop13, DuraGo14, and Akebono15?

Overwhelmed by all the brake rotor choices16? Comparing brands like Bosch, PowerStop13, and DuraGo14 can be difficult. We will give you a clear comparison to simplify your decision.

Bosch rotors1 are the OE-quality benchmark17 for quiet, reliable daily driving. PowerStop13 focuses on performance upgrade kits. DuraGo14 is a solid budget-friendly option18. Akebono15 is another top-tier OE supplier, making them a direct competitor to Bosch in terms of quality.

Choosing the right rotor brand depends on what you need. Are you replacing a worn-out part on your family car, or are you upgrading your sports car for better performance? As someone who sees the specs for many different brands, I can break down the main players for you.

Defining the Competitors

- Bosch: Think of Bosch as the reliable, gold standard for OE replacement. Their goal is to make a rotor that performs just like the one that came on your car from the factory, or slightly better. The focus is on smooth, quiet, and dependable braking for everyday driving.

- PowerStop13: This brand is all about performance upgrades. They are famous for their drilled and slotted rotors, which are designed to cool better and vent gases under heavy braking. They are a great choice for enthusiasts, but the slots and holes can sometimes create more noise and wear out brake pads faster.

- DuraGo14: DuraGo14 is a strong player in the value market. They offer a huge range of rotors that provide safe, reliable performance at a very competitive price. They are a great choice for a daily driver when the budget is a primary concern.

- Akebono15: Akebono15 is a giant in the automotive world, especially famous for their brake pads. They are a top-tier OE supplier, just like Bosch. Their rotors are engineered to the same high standards, and in many cases, they are direct competitors for the same vehicle contracts. Choosing between Bosch and Akebono15 often comes down to price or availability.

Choosing Based on Your Needs

There is no single "best" brand for everyone. The right choice is the one that matches your car and how you drive it.

| Brand | Target User | Key Feature | Price Point |

|---|---|---|---|

| Bosch | Daily Driver (OE Replacement) | Quiet, Smooth, OE-Quality | Mid to High |

| PowerStop13 | Enthusiast (Performance Upgrade) | Drilled & Slotted, Improved Cooling | Mid to High |

| DuraGo14 | Budget-Conscious Driver | Value and Reliability | Low to Mid |

| Akebono15 | Daily Driver (OE Replacement) | OE-Quality, System-Matched | Mid to High |

Conclusion

In short, Bosch rotors1 are a benchmark for OE-level quality and reliability. However, the best choice always depends on your car, your driving habits, and your budget.

Explore the unique features of Bosch rotors that make them a preferred option for vehicle safety. ↩

Learn how high-carbon material enhances brake performance and durability. ↩

Discover the importance of precision engineering in ensuring effective braking. ↩

Understand how effective heat management can improve braking safety and performance. ↩

Gain insights into the role of OEM suppliers in manufacturing high-quality auto parts. ↩

Explore Bosch's rigorous quality control measures that ensure consistent product quality. ↩

Discover the intricate machining process that ensures the precision of Bosch rotors. ↩

Learn about the advantages of using high-carbon cast iron in brake rotor manufacturing. ↩

Understand the phenomenon of brake fade and how Bosch rotors help mitigate it. ↩

Learn about the factors that lead to steering wheel shimmy and how to prevent it. ↩

Explore the cutting-edge technology that enables the production of high-quality rotors. ↩

Learn about the strict material specifications that Bosch enforces for its rotors. ↩

Get a clear comparison between Bosch and PowerStop rotors to make an informed choice. ↩

Explore the benefits of DuraGo rotors and how they stack up against Bosch. ↩

Find out how Bosch and Akebono rotors differ in terms of quality and performance. ↩

Learn about the key factors to consider when selecting the right brake rotors for your vehicle. ↩

Understand the significance of OE-quality benchmarks in ensuring reliable brake performance. ↩

Discover affordable brake rotor options that still provide reliable performance. ↩